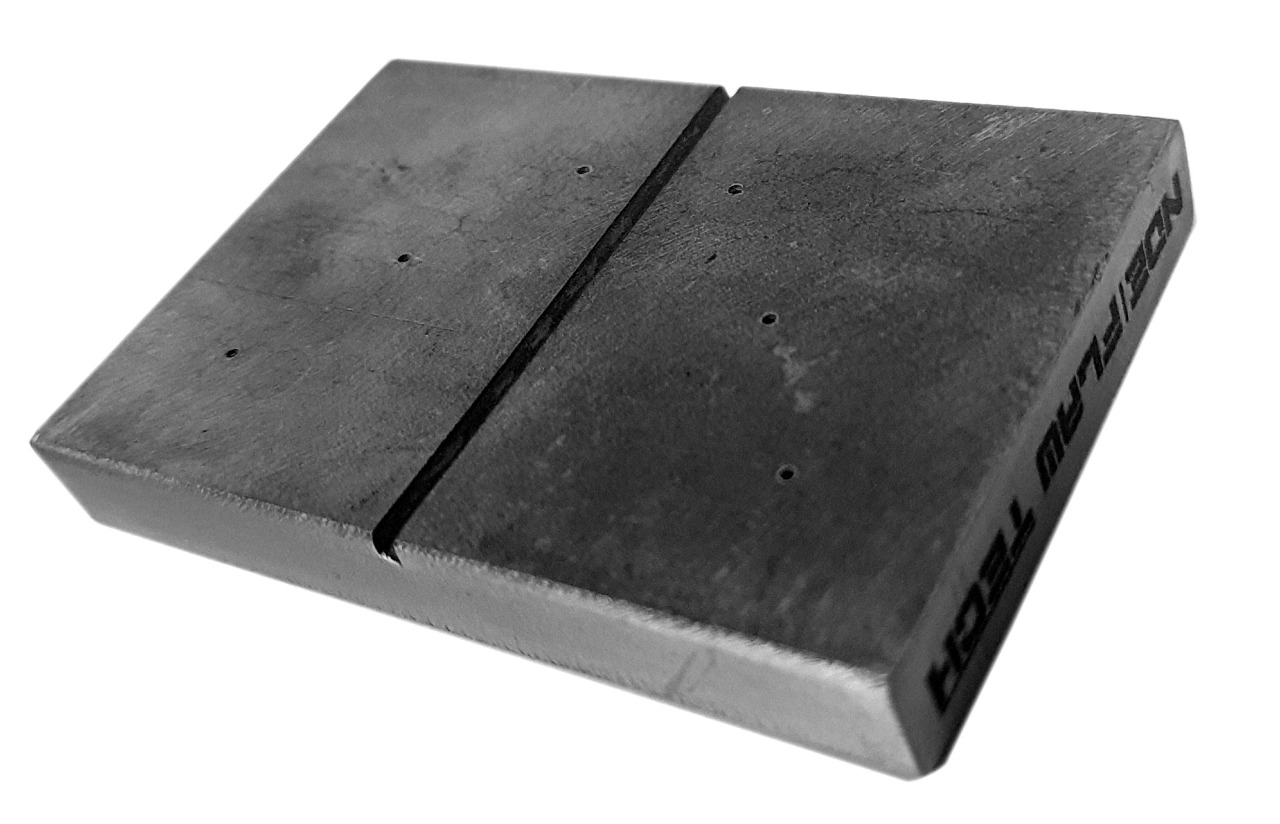

Aluminum Test Block (for Sensitivity)

Aluminum Test Block (for Sensitivity) Aluminum Test Block (for Sensitivity) Cracked aluminum block compares sensitivity of different penetrants or sensitivity of new and old penetrants. The Aluminum Test Block is an aluminum test piece that measures 3? (75mm) x 2? (50mm) x 3/8? (9.5mm) with a 1/8? (3.2mm) wide with a milled notch that separates the blocks two sides to facilitate side-by-side penetrant comparison. The test block is used to check the strength of “in-use” penetrants. This is done by processing one half of the block with “used” penetrant, and the other half with fresh penetrant.

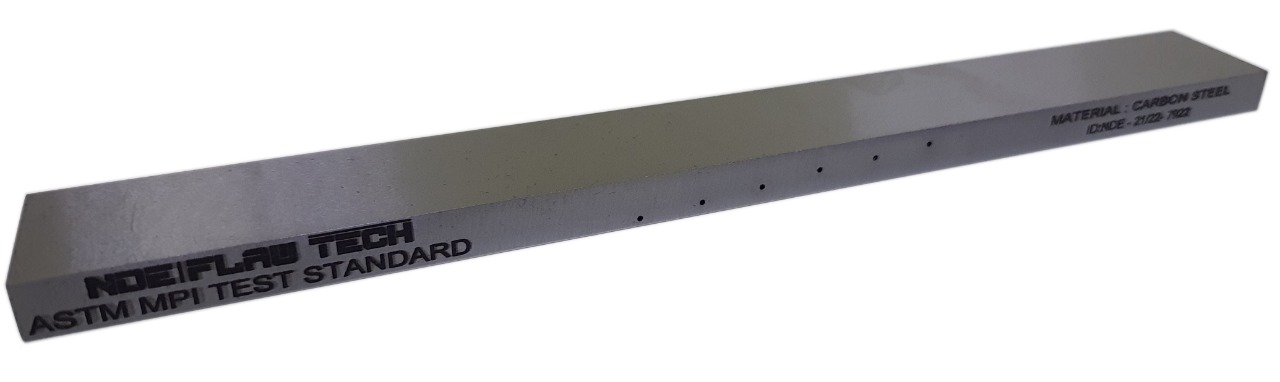

ASTM Test block (MPT)

ASTM Test block (MPT) ASTM test block is also known as MPT test bar used in Magnetic particle inspection. It has 7 numbers of artificial flaws (side drilled holes). Easy to carry on site. Pocket friendly. ASTM MPI Test Block is used in magnetic particle inspection will help you maintain your magnetic particle process by verifying magnetic particle performance. Use to check for magnetic particle deterioration, to compare different magnetic powders, to verify sensitivity or visibility or to assure field direction and strength. It contains coarse and fine surface and subsurface defects in both directions. Meets or exceeds most industrial and military standards for artificial test specimens and complies with MIL-STD-271. BLOCK DIMENSION – 255mm (L) X 30mm (W) X 10mm (T) Block Contains 7 HOLES HOLES DIA – Ø1.2mm HOLES DEPTH – 20mm

Permanent Magnet Yokes

Permanent Magnet Yokes General Details: Permanent Magnet Yokes are a great convenience in Magnetic Particle Inspection, due to their complete portability, as no electricity is required. Lifting capacity at 100mm pole distance 50 Pounds (23 Kg). The specially shaped pole pieces permit easy removal of the pole pieces from the component The PMY Yoke is a portable permanent magnet Yoke which is ideal for magnetizing components for crack detection, Consists of hinged arms to allow a wide variety of profiles to be magnetized. Features: Lightweight, Economical, Versatility and powerful performance. Safe and secured for operators. Easy to Use, Compact, No Recharging, Durable, Hinged Frame, Powerful magnets with rotating head. Suitable for continuous inspection. Strong and rugged construction, Hazardous Zones Portable. PMY Yoke complies with ASTM E709 & ASME Section V Article 7. TECHNICAL SPECIFICATIONS. Magnetic elements: Magloy1 Pole Spacing:0-12” (0-300mm) Lifting capacity: 100mm pole distance 23 Kg Field Strength with Tips in Contact: 9000 Gauss Field Strength with 2” (50mm) Air Gap:650 Gauss Weight: 2.5 Kg Uses: • Automotive • Pressure Equipment • Manufacturing • Aerospace • Piping • Fabrication • Weld Inspection Standard package includes: Permanent Yoke. Carry Case. Operation Manual. Calibration Certificate.

MPI.jpeg)

Yoke Weight Lift Test Block (18.0kg)

Yoke Weight Lift Test Block(18.0kg) Mpi Weight Lift block (18.0kg) AC yokes 4.5Kg with Carrying Handle. Permanent Magnet Test Weight 18Kg with Carrying Handle American Standard 22.5Kg Yoke Weight lift test block (18.0kg) Lift Test Weights The weights are required to test the magnetic field produced by Electro-Magnets and Permanent Magnets to ensure parts are being sufficiently inspected when using MPI methods of NDT • Electromagnetic Yoke Test Weight for use with AC yokes 4.5Kg with Carrying Handle. • Permanent Magnet Test Weight 18Kg with Carrying Handle • American Standard 22.5Kg

Yoke Weight Lift Test Block (4.5kg)

Yoke Weight Lift Test Block (4.5kg) MPI Weight Lift block (4.5kg) AC yokes 4.5Kg with Carrying Handle. Permanent Magnet Test Weight 18Kg with Carrying Handle American Standard 22.5Kg Yoke Weight lift test block (4.5kg) Lift Test Weights The weights are required to test the magnetic field produced by Electro-Magnets and Permanent Magnets to ensure parts are being sufficiently inspected when using MPI methods of NDT • Electromagnetic Yoke Test Weight for use with AC yokes 4.5Kg with Carrying Handle. • Permanent Magnet Test Weight 18Kg with Carrying Handle • American Standard 22.5Kg

Pie Gauge

Pie Gauge The pie gauge is a disk of highly permeable material divided into four, six, or eight sections by non-ferromagnetic material. The divisions serve as artificial defects that radiate out in different directions from the center. The diameter of the gauge is 3/4 to 1 inch. The divisions between the low carbon steel pie sections are to be no greater than 1/32 inch. The sections are furnace brazed and copper plated. The gauge is placed on the test piece copper side up and the test piece is magnetized. After particles are applied and the excess removed, the indications provide the inspector the orientation of the magnetic field. The principal application is on flat surfaces such as weldments or steel castings where dry powder is used with a yoke or prods. The pie gauge is not recommended for precision parts with complex shapes, for wet-method applications, or for proving field magnitude. The gauge should be demagnetized between readings. Several of the main advantages of the pie gauge are that it is easy to use and it can be used indefinitely without deterioration. The pie gauge has several disadvantages, which include: it retains some residual magnetism so indications will prevail after removal of the source of magnetization, it can only be used in relatively flat areas, and it cannot be reliably used for determination of balanced fields in multidirectional magnetization.

QQI Standard KSC-230

QQI Standard KSC-230 Basic circular and crossed bar flaw configuration suitable for longitudinal and circular fields. The standard flawed shims are typically used to establish proper field direction and ensure adequate field strength during technique development in magnetic particle examination. The Shims may be used to ensure the establishment and balance of field in the multi-directional magnetization method. The use of a QQI is also the only practical way of ensuring balanced field intensity and direction in multiple-direction magnetization equipment. QQIs are often used in conjunction with a Gauss meter to establish the inspection procedure for a particular component. They are used with the wet method only, and like other flux sharing devices, can only be used with continuous magnetization. 30% of Shim thickness, .002” thick (0.05 mm)

QQI Miniature KSC-4-230

QQI Miniature KSC-4-230 Similar to KSC230, except miniature design for small areas on test part. The four circles may be cut apart for individual use. Basic circular and crossed bar flaw configuration suitable for longitudinal and circular fields. The standard flawed shims are typically used to establish proper field direction and ensure adequate field strength during technique development in magnetic particle examination. The Shims may be used to ensure the establishment and balance of field in the multi-directional magnetization method. The use of a QQI is also the only practical way of ensuring balanced field intensity and direction in multiple-direction magnetization equipment. QQIs are often used in conjunction with a Gauss meter to establish the inspection procedure for a particular component. They are used with the wet method only, and like other flux sharing devices, can only be used with continuous magnetization. 30% of Shim thickness, .002” thick (0.05 mm)

QQI Variable Depth KSCT-234

QQI Variable Depth KSCT-234 Used for more quantitative work, three concentric circular flaws of differing depth. Basic circular and crossed bar flaw configuration suitable for longitudinal and circular fields. The standard flawed shims are typically used to establish proper field direction and ensure adequate field strength during technique development in magnetic particle examination. The Shims may be used to ensure the establishment and balance of field in the multi-directional magnetization method. The use of a QQI is also the only practical way of ensuring balanced field intensity and direction in multiple-direction magnetization equipment. QQIs are often used in conjunction with a Gauss meter to establish the inspection procedure for a particular component. They are used with the wet method only, and like other flux sharing devices, can only be used with continuous magnetization. 20%/30%/40% of Shim thickness, .002” thick (0.05 mm)

QQI Variable Depth KSC4-234

QQI Variable Depth KSC4-234 Used for more quantitative work, three concentric circular flaws of differing depth. Basic circular and crossed bar flaw configuration suitable for longitudinal and circular fields. The standard flawed shims are typically used to establish proper field direction and ensure adequate field strength during technique development in magnetic particle examination. The Shims may be used to ensure the establishment and balance of field in the multi-directional magnetization method. The use of a QQI is also the only practical way of ensuring balanced field intensity and direction in multiple-direction magnetization equipment. QQIs are often used in conjunction with a Gauss meter to establish the inspection procedure for a particular component. They are used with the wet method only, and like other flux sharing devices, can only be used with continuous magnetization. 20%/30%/40% of Shim thickness, .004” thick (0.1 mm)

Ketos Ring

Ketos Ring the Ketos Ring is used to check overall performance of the magnetic particle examination system. Prior to the inspection, a system performance verifier is often used to ensure that the system is delivering the proper amount of current as called for during the inspection. Within the NDE industry there is a number of different standard process control specimens used to aid in verifying the performance of the electromagnetic system. The Ketos ring is a ring that is made up of a series of pre-drilled holes at increasing depths below the surface used to simulate sub-surface defects. The distance of the holes to the surface increases as you move to holes of increasing number. Its original purpose was to demonstrate the ability to use MPI to find sub-surface flaws, but it has long since been used to perform regular performance evaluation of MPI bench systems. The intensity of the indication depends on the depth of the flaw and the amount of current passed through a central bar conductor.

MTU Test Block

MTU Test Block NDEFLAW-MTU-11 MPI MTU Calibration Block Used to test the sensitivity of Wet Method MPI Baths. Quick and easy verification and comparison of magnetic particle materials. The MTU-3 Test Block is used to check the sensitivity of magnetic-particle materials. This two-sided block has a variety of indications ranging in size from small to large. Use the MTU-3 to compare

Central Conductor Dia1.00″ L 15.875″

These solid copper rods (copper type 110) provide circular magnetization of hollow parts.

Central Conductor Dia 0.5″ L 15.875″

Central Conductor Dia 0.5″ L 15.875″ These solid copper rods (copper type 110) provide circular magnetization of hollow parts.

Central Conductor Dia 0.75″ L 15.875"

Central Conductor Dia 0.75″ L 15.875" These solid copper rods (copper type 110) provide circular magnetization of hollow parts.

Central Conductor Kit, each of .50″, .75″& 1.00″

Central Conductor Kit, each of .50″, .75″& 1.00″ Central Conductor Kit, Includes one each of Dia.5″ L 15.875″, .Dia.75″ L 15.875" Dia1.00″ L 15.875″″ these solid copper rods (copper type 110) provide circular magnetization of hollow parts.

Copper Pad

Copper Pad Copper Pad (5″x7″) Used to prevent arc burn by helping to maintain proper electrical contact between test parts and contact heads.

Copper Pad Assembly

Copper Pad Assembly (2 Copper Pads & V-Block) Double-Braided Pad with V-Block. Heavy copper braid provides contact over greater surface area. Built with neoprene, the V-block base centers and supports test parts. The pad can be reversed to provide two wear faces. Fits all units except A-915 and the smaller MAG Series units.

Large Copper Pad (5″x10″)

Large Copper Pad (5″x10″) Large Copper Pad (5″ x 10″) Used to prevent arc burn by helping to maintain proper electrical contact between test parts and contact heads.

Large Copper Pad Assembly (12"x12")

Large Copper Pad Assembly (12"x12") Large Copper Pad Assembly 12" x 12" (2 Copper Pads & V-Block) Double-Braided Pad with V-Block. Heavy copper braid provides contact over greater surface area. Built with neoprene, the V-block base centers and supports test parts. The pad can be reversed to provide two wear faces. Replaces standard pads with no modifications needed.

Heavy Duty Lead Contact Plate

Heavy Duty Lead Contact Plate. Copper impregnated lead contact plate that lasts 10 times longer than lead contact plates. Size: 6-3/4” (171.45mm) x 6-5/8” (168.275mm) x 1/4” (6.35mm) thick Fits all units except A-915 and the smaller MAG Series units.

Lead Contact Plate

Duplicates original headstock/tailstock contact plates. The soft lead provides excellent contact with test part. Size: 6-3/4” (171.45mm) x 6-5/8” (168.275mm) x 1/4” (6.35mm) thick. (Fits all units except A-915 and the smaller MAG Series units.)

Magnetic Flux Indicators, Type G, Set of 5

Magnetic Flux Indicators Flexible indicators used to detect appropriate levels of magnetic field strength and directional orientation during the magnetic particle testing process. Each indicator contains three milled slots with widths of .0075", .009" and .010" that share a common depth. The indicators are manufactured from permeable magnetic steel sandwiched between two brass plates and designed for repeated use in setting and monitoring magnetic field strength in wet and dry MPI applications. Meets ASTM E 1444-11, Annex A3 specifications.

QQI Standard KSC-430

Basic circular and crossed bar flaw configuration suitable for longitudinal and circular fields. The standard flawed shims are typically used to establish proper field direction and ensure adequate field strength during technique development in magnetic particle examination. The Shims may be used to ensure the establishment and balance of field in the multi-directional magnetization method.

NA-16 Notch Defect Test Bar

NA-16 Notch Defect Test Bar the NA-16 Notch Test Bar complies with the requirements of MIL-STD-271E and F (Ships), paragraph 4.3.1.2, and NAVSEA-TB-T9074-AS-GIB-010/271. The procedure specifies an inspection with the ability to detect the smallest rejectable surface defects, artificial or natural, in a test specimen. For the inspection of welds, the magnetic particle inspection procedure shall have the proven ability to detect a 1 ⁄16-inch long by 0.006 inch wide by 0.020 inch deep notch (maximum dimensions) oriented 90 degrees to the magnetic flux. The notch shall be cut in a 3 ⁄8-inch low alloy steel plate, and shall be filled flush with a non-conducting material, such as epoxy, to prevent mechanical holding of the indication medium.

Stainless Steel Test Block (for Washability)

Stainless Steel TEST BLOCK (for washability) the stainless steel test block offers a simple and convenient comparator for monitoring washability of water-wash or post-emulsified penetrants. The “grit blasted” finish provides a rough surface which will retain background when the removability of a product has decreased when compared to fresh material. The test block should be thoroughly cleaned with Cleaner/Remover, as well as periodically refinished (grit blast). Specifications Compliance: Complies with ASTM E165.

NiCr 10 micron panels (One Pair)

NiCr Test Panels are ideal comparators to test penetrant sensitivity.

NiCr 20 micron panels (One Pair)

NiCr Test Panels are ideal comparators to test penetrant sensitivity.

NiCr 30 micron panels (One Pair)

NiCr 30 micron panels (One Pair) NiCr Test Panels are ideal comparators to test penetrant sensitivity. Dimensions: Length 100mm ± 2mm Width 35mm ± 2mm Thickness 2mm ± 0.2mm

NiCr 50 micron panels (One Pair)

NiCr Test Panels are ideal comparators to test penetrant sensitivity.