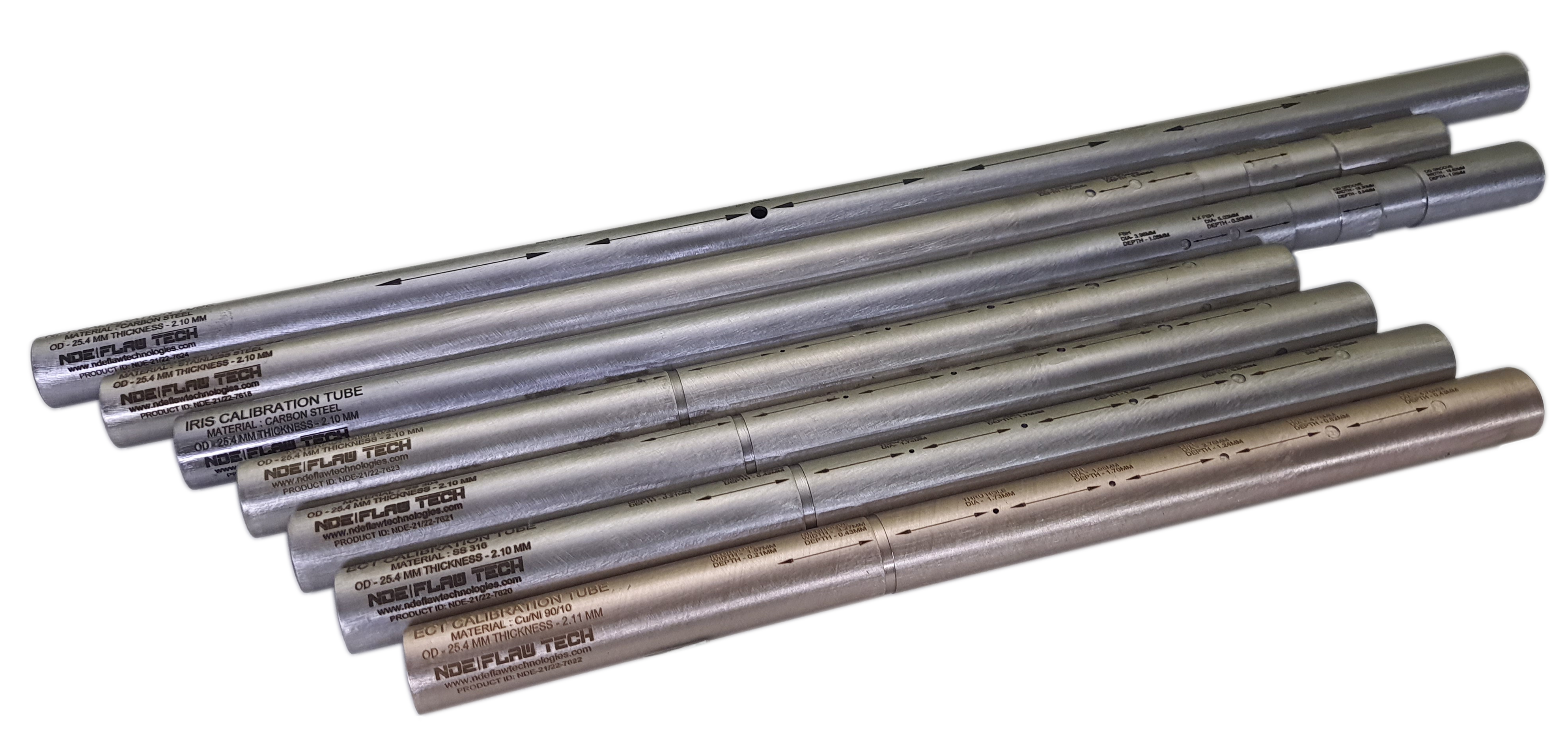

Magnetic Flux Leakage Calibration Tube

Price: $0.00

Part Number : NDE FLAW TECH-MFL CALIBRATION TUBE-37

Availability : In Stock

Description

Magnetic Flux Leakage Calibration Tube

Eddy Current Tube Standards. Ready

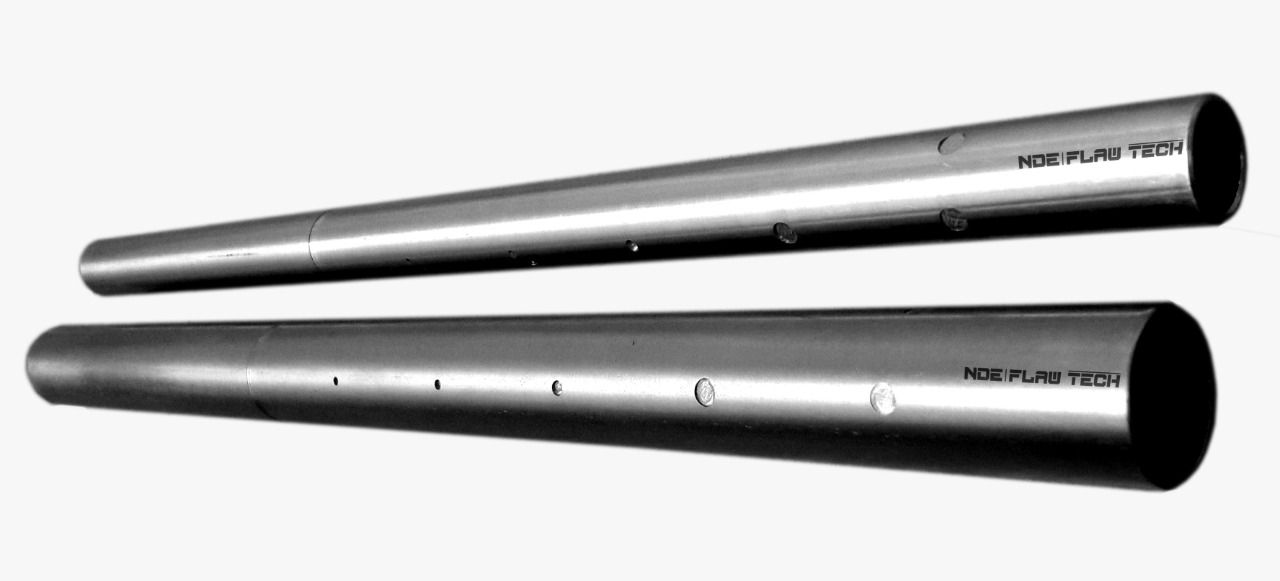

to request a quote for a standard? Here's what we need... What is the material?

(Alloy, OD and Wall) Is NDE

supplying the material or will it be customer supplied? What defects are needed

and what size? (Most depths are given in % of tube wall) Is there a

specification the standard needs to comply with? (ASME, etc.) If you have

a drawing, or

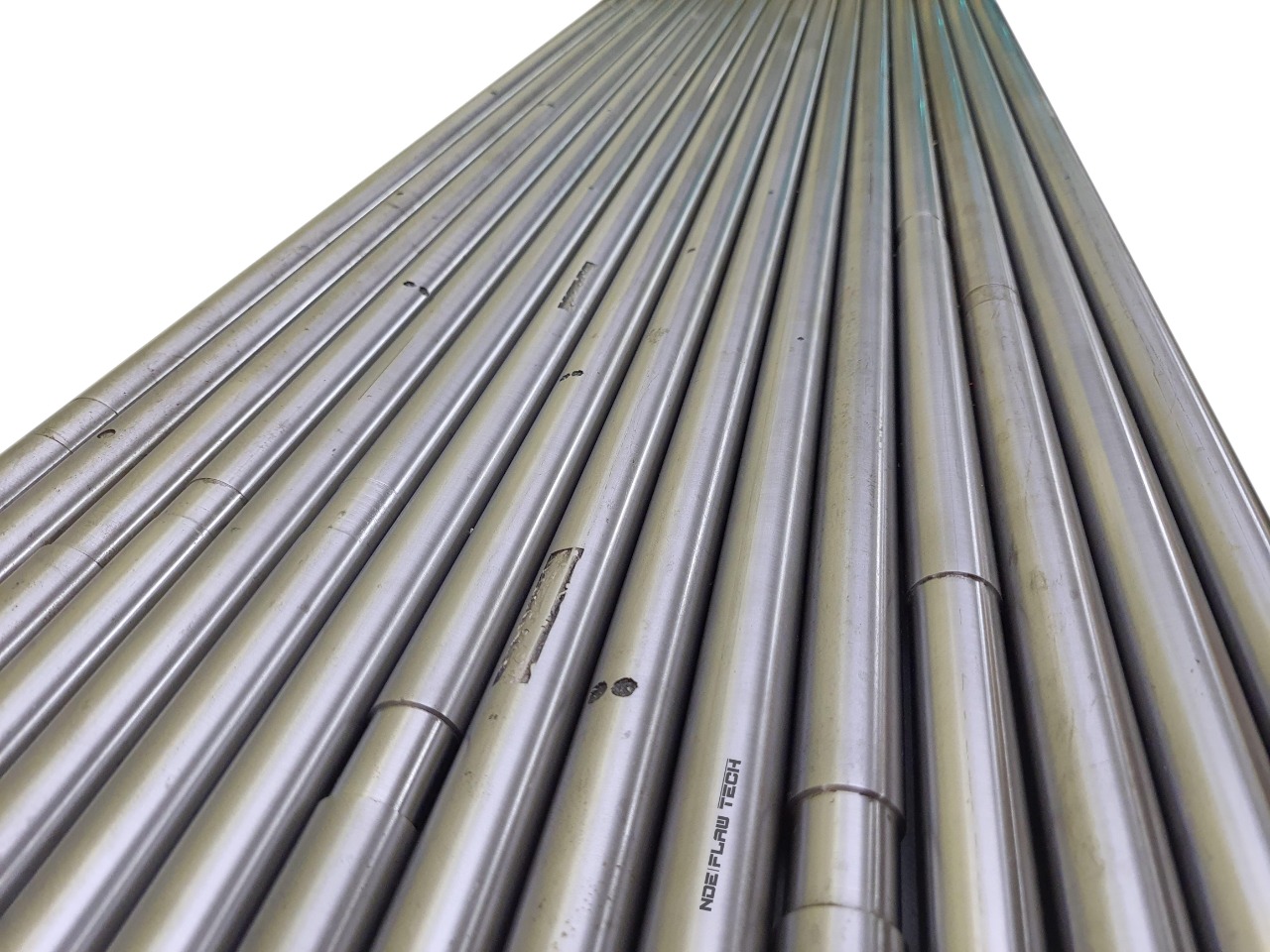

even a simple hand sketch, please send that along as well. We specialize in

custom eddy current tubes, and have years of experience in machining a huge range of defects.

From TWHs and FBHs, OD and ID grooves, milled flats, and OD and ID thinning

bands, to ID FBHs, ID contoured flats, 120°/180° wears cars, tapered flaws, and tube-to-tube wear,

|

Application |

Description |

MFL |

Comments |

|

Heat Exchangers |

|||

|

Mildly ferromagnetic material Duplex steel, SS439,

Secure, Monel |

X |

– ECT is used only for thin tubes (<1.6 mm) with saturation

probes.- For thicker walls, it is better to use RFT or MFL.- IRIS can

sometimes be used to confirm the sizing of defects. |

|

|

Ferromagnetic material Carbon steel, nickel.

Typical defects are pitting and corrosion. |

X |

– RFT, MFL, and IRIS are good, and most of the time

complementary. |

|

|

Air Coolers |

Carbon steel tube with aluminum fins Typical defects are ID

pitting and OD wear close to the water box. |

X |

– RFT is not effective because the fins disturb the remote

field.- MFL is quick and sensitive but does not allow sizing.- IRIS is often

used to back up MFL but has difficulty with OD flaws. |

|

Boilers |

Carbon steel tube Typical defects are pitting,

wear, and cracking at the tube sheet. |

X |

– RFT is good for wear detection and can easily pass the

bend.- MFL is good only on straight boiler tubes without swages.- IRIS is

good for wear and pits but has no sensitivity in the bend. |

.jpg)

.png)

.png)