FLAT BOTTOM VACUUM BOX BUBBLE LEAK TESTING

Price: $729.00

Part Number : NDE FLAW TECH-VB-5801

Availability : In Stock

Description

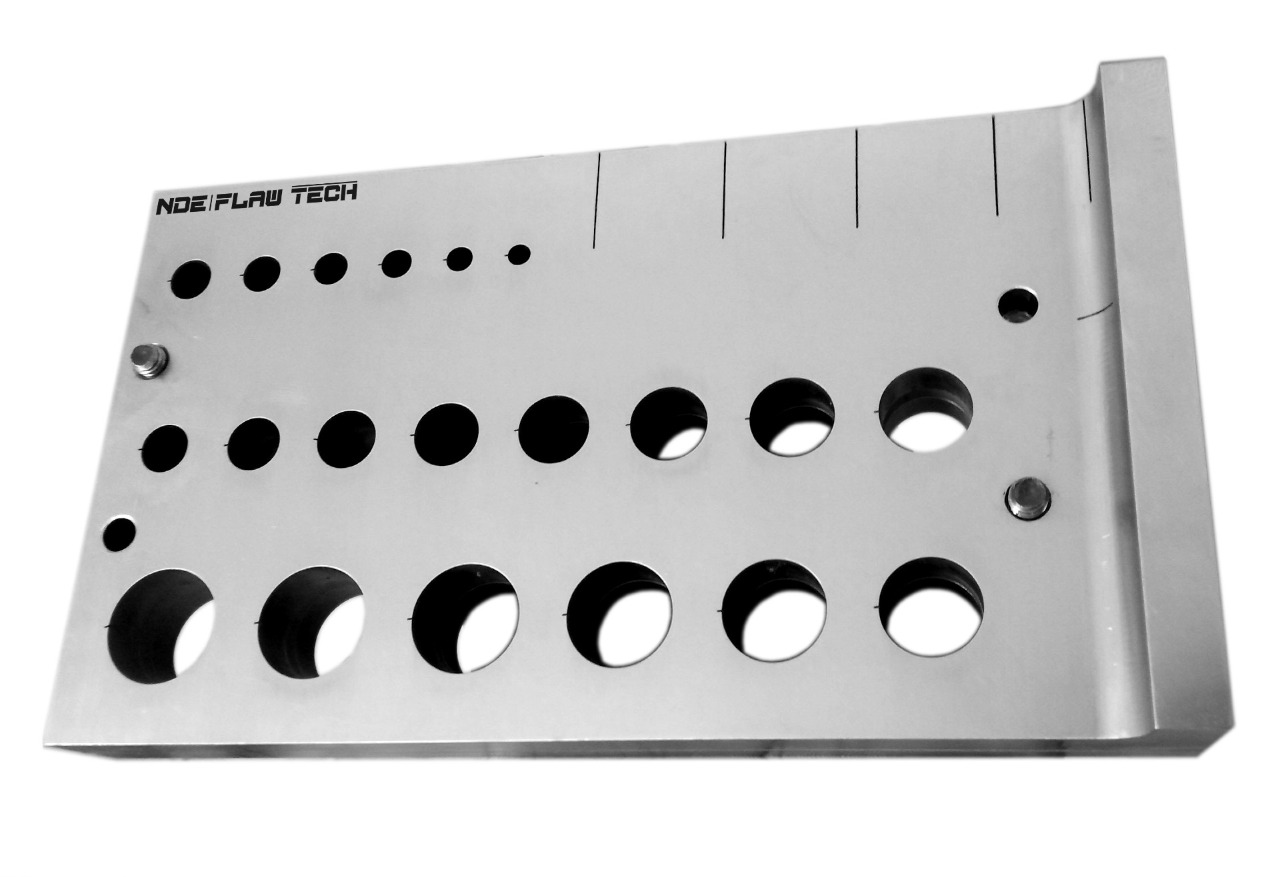

FLAT BOTTOM VACUUM BOX BUBBLE LEAK TESTING

Vacuum box testing is a non-destructive

examination (NDE/NDT) used for locating welding leaks. A vacuum box and a

compressor create a high or low-pressure vacuum and a detergent solution is

applied to the test area. The detergent bubbles help to identify the leaks

within the created pressure envelope. The main objective of the Vacuum box

testing technique is to locate leaks in welds due to through-thickness

discontinuities. This is accomplished by applying a solution to a weld and

creating a differential pressure across the weld causing the formation of

bubbles as leakage gas passes through the solution. This testing is to be

performed prior to any main vessel or tank testing following the completion of

all welding. This article will briefly explain the leak testing procedure using

the vacuum box method that can be used for all metals.

1-Flat Bottom box for testing butt welds on flat surfaces

2-Operates using compressed air

• Dimensions: 600mm X 200mm X 150mm

Note:

Customized VACUUM BOX also available.

.jpeg)