Inch Version

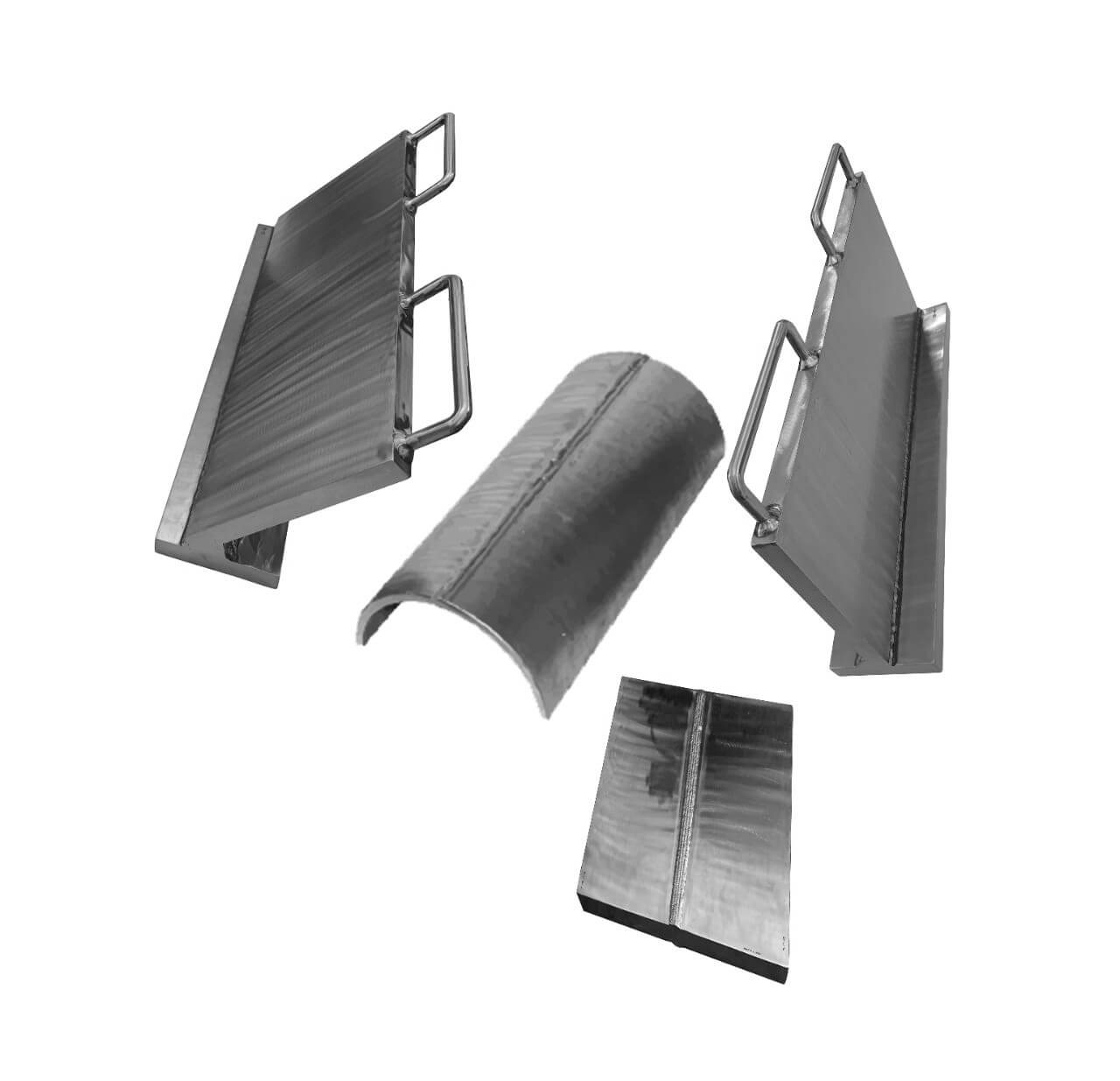

API RP-2X Practice Test Kit (INCH VERSION)

API RP-2X Practice Test Kit (INCH VERSION) Designed in the spirit of API RP-2X, these specimens offer a technician advanced training in UT flaw detection & sizing in unique configurations. This kit is a great tool for conducting practical examinations, as well as preparing technicians for typical industry exams. Total of 4 specimens • 90° “T” Connection, 0.75” (T) x 12” (weld length) x 4” (Base) x ~8” (leg) • 60° Diagonal “Y” Connection, 0.75” (T) x 12” (weld length) x 4” (Base) x ~8” (leg) • Simulated Plate 1” T x 12” (weld length) x ~12” (~6” either side of weld center line) with 0.25” x 1” Backing Bar • Pipe Longitudinal Weld 8” Sch60 (0.406”) x 12” x ~180° segment (~6” either side of longitudinal weld center line) Flaws: • Total of 11 flaws • Flaws are randomly placed ~2-4 flaw per specimen • Flaw design and manufacturing intent is to make all flaws rejectable as per API RP-2X Level C acceptance criteria (Fig. 45 & 48). • Flaw acceptability must be determined by the end user and will not be determined by ultrasonic during or post manufacturing. Documentation: • Includes Certificate of Conformance, “As Built” CAD drawings, “Blank” CAD Test Sheets, UT Inspection Report and Measuring & Test Equipment Certificates

Metric Version

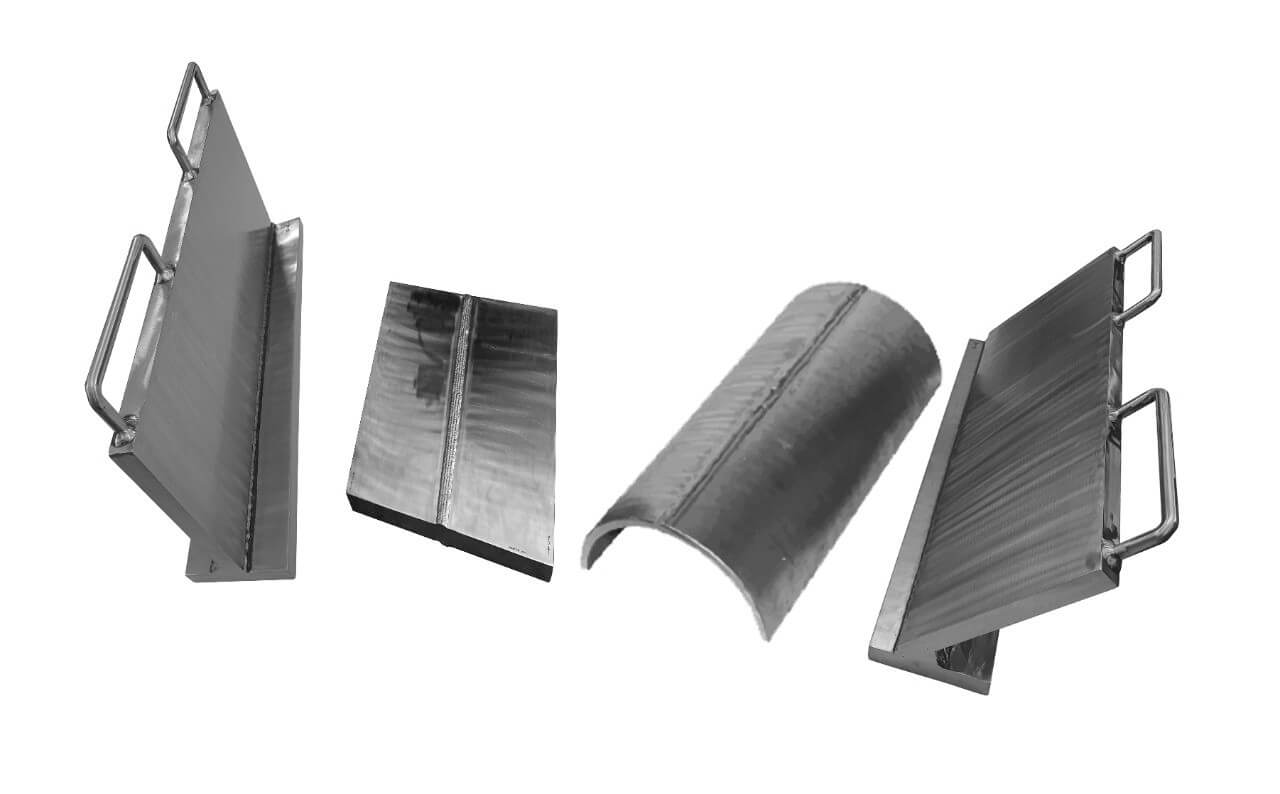

API RP-2X Practice Test Kit (METRIC VERSION)

API RP-2X Practice Test Kit (METRIC VERSION) Designed in the spirit of API RP-2X, these specimens offer a technician advanced training in UT flaw detection & sizing in unique configurations. This kit is a great tool for conducting practical examinations, as well as preparing technicians for typical industry exams. Total of 4 specimens • 90° “T” Connection, 19mm (T) x 300mm (weld length) x 100mm (Base) x 200mm (Branch) • 60° Diagonal “Y” Connection, 19mm (T) x 300mm (weld length) x 100mm (Base) x 200mm (Branch) • Simulated Plate 25mm (T) x 300mm (weld length) x 300mm (150mm either side of weld center line) with 6mm x 25mm Backing Bar • Pipe Longitudinal Weld 219mm Sch60 (10mm) x 300mm x ~180° segment (150mm either side of longitudinal weld center line) Flaws: • Total of 11 flaws • Flaws are randomly placed ~2-4 flaw per specimen • Flaw design and manufacturing intent is to make all flaws rejectable as per API RP-2X Level C acceptance criteria (Fig. 45 & 48). • Flaw acceptability must be determined by the end user and will not be determined by ultrasonic during or post manufacturing. Documentation: • Includes Certificate of Conformance, “As Built” CAD drawings, “Blank” CAD Test Sheets, UT Inspection Report and Measuring & Test Equipment Certificates