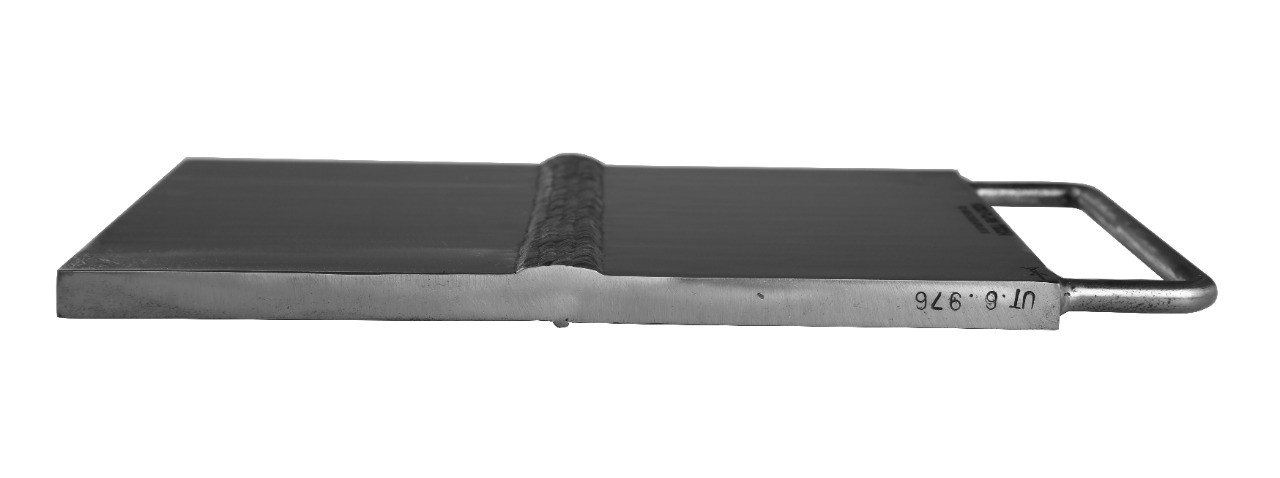

Plate Ultrasonic Test Practical Exam Flaw Specimen 0.4” SINGLE-V (Inch Version) Carbon Steel

Plate Ultrasonic Test Practical Exam Flaw Specimen 0.4” SINGLE-V (Inch Version) Carbon Steel Plate Ultrasonic Test Practical Exam Flaw Specimen Plate Ultrasonic Practical Exam flawed Test specimens. Geometry: 0.4” (T) x 8.0” (W) x 10.0” (L). Flaws: 3, randomly placed Standard Tolerance: +/-4mm. Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available.

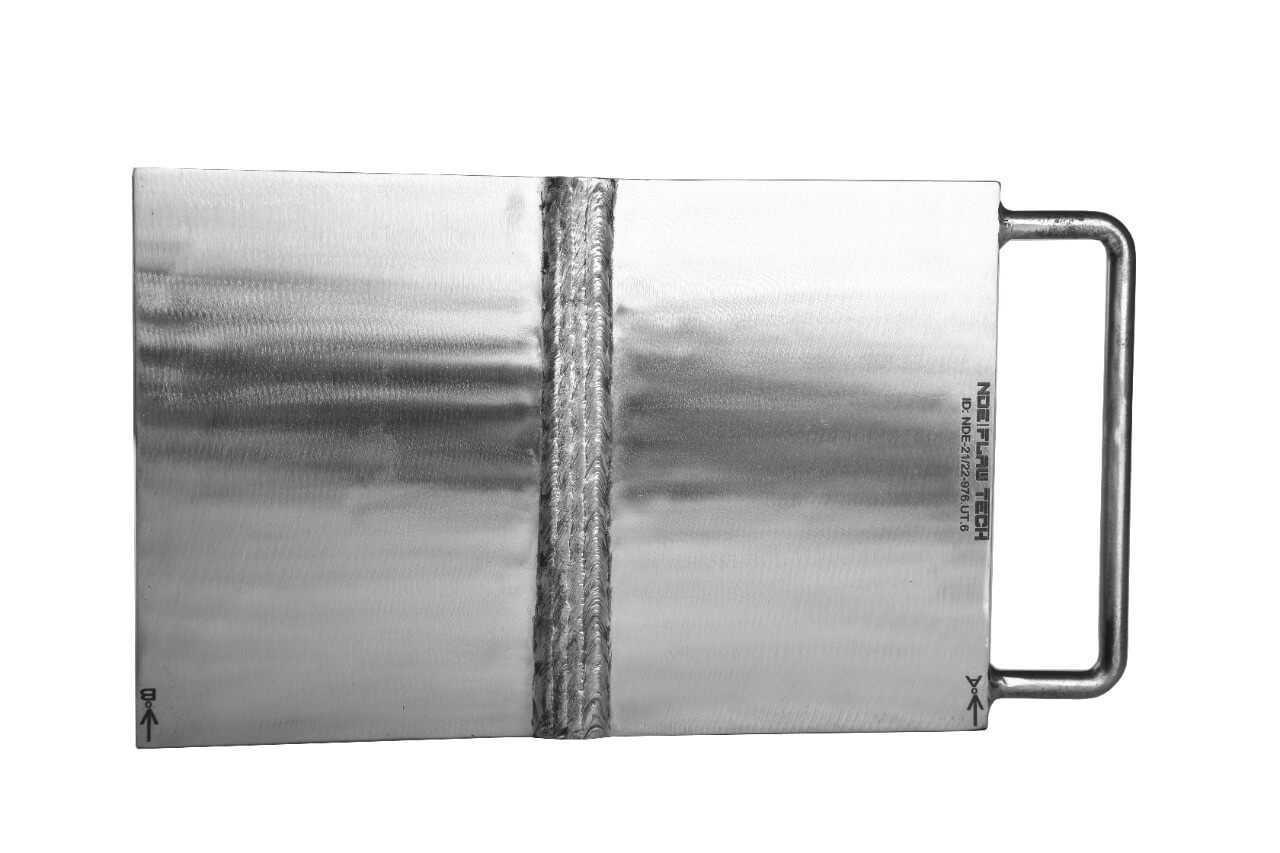

Plate Ultrasonic Test Practical Exam Flaw Specimen 0.8” DOUBLE-V (Inch Version)

Plate Ultrasonic Test Practical Exam Flaw Specimen 0.8” DOUBLE-V (Inch Version) Plate Ultrasonic Test Practical Exam Flaw Specimen Plate Ultrasonic Practical Exam flawed Test specimens. Geometry: 0.8” (T) x 8.0” (W) x 10.0” (L). Flaws: 3, randomly placed Standard Tolerance: +/-4mm. Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available.

Pipe Ultrasonic Test Practical Exam Flaw Specimen Ø3” (Inch Version) Carbon Steel

Pipe Ultrasonic Test Practical Exam Flaw Specimen Ø3” (Inch Version) Carbon Steel Pipe Ultrasonic Test Practical Exam Flaw Specimen Pipe Ultrasonic Practical Exam flawed Test specimens. Geometry: 0.4” (T) x Ø3” x 12.0” (L). Flaws: 3, randomly placed Standard Tolerance: +/-4mm. Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available.

Pipe Ultrasonic Test Practical Exam Flaw Specimen Ø4” (Inch Version) Carbon Steel

Pipe Ultrasonic Test Practical Exam Flaw Specimen Ø4” (Inch Version) Carbon Steel Pipe Ultrasonic Test Practical Exam Flaw Specimen Pipe Ultrasonic Practical Exam flawed Test specimens. Geometry: 0.4” (T) x Ø4” x 12.0” (L). Flaws: 3, randomly placed Standard Tolerance: +/-4mm. Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available.

Pipe Ultrasonic Test Practical Exam Flaw Specimen Ø6” (Inch Version) Carbon Steel

Pipe Ultrasonic Test Practical Exam Flaw Specimen Ø6” (Inch Version) Carbon Steel Pipe Ultrasonic Test Practical Exam Flaw Specimen Pipe Ultrasonic Practical Exam flawed Test specimens. Geometry: 0.6” (T) x Ø6” x 12.0” (L). Flaws: 3, randomly placed Standard Tolerance: +/-4mm. Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available.

T-Plate Ultrasonic Test Practical Exam Flaw Specimen 0.4” SINGLE-V (Inch Version) Carbon Steel

T-Plate Ultrasonic Test Practical Exam Flaw Specimen 0.4” SINGLE-V (Inch Version) Carbon Steel T-Plate Ultrasonic Test Practical Exam Flaw Specimen T-Plate Ultrasonic Practical Exam flawed Test specimens. Geometry: 0.4” (T) x 8.0” (W) x 10.0” (L) x 10.0” (H). Flaws: 3, randomly placed Standard Tolerance: +/-4mm. Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available.

T-Plate Ultrasonic Test Practical Exam Flaw Specimen 0.8” DOUBLE-V (Inch Version) Carbon Steel

T-Plate Ultrasonic Test Practical Exam Flaw Specimen 0.8” DOUBLE-V (Inch Version) Carbon Steel T-Plate Ultrasonic Test Practical Exam Flaw Specimen T-Plate Ultrasonic Practical Exam flawed Test specimens. Geometry: 0.8” (T) x 8.0” (W) x 10.0” (L) x 10.0” (H). Flaws: 3, randomly placed Standard Tolerance: +/-4mm. Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available.

Plate Ultrasonic Test Practical Exam Flaw Specimen 0.75" SINGLE-V (Inch Version) Carbon Steel

Plate Ultrasonic Test Practical Exam Flaw Specimen 0.75" (Inch Version) Carbon Steel Plate Ultrasonic Test Practical Exam Flaw Specimen Plate Ultrasonic Practical Exam flawed Test specimens. Geometry: 0.75" x 8" x 10". Flaws: 3, randomly placed Standard Tolerance: +/-0.150" (4mm). Documentation: NDT Verification Reports,C of C, CAD Drawings and Test Sheets. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available.

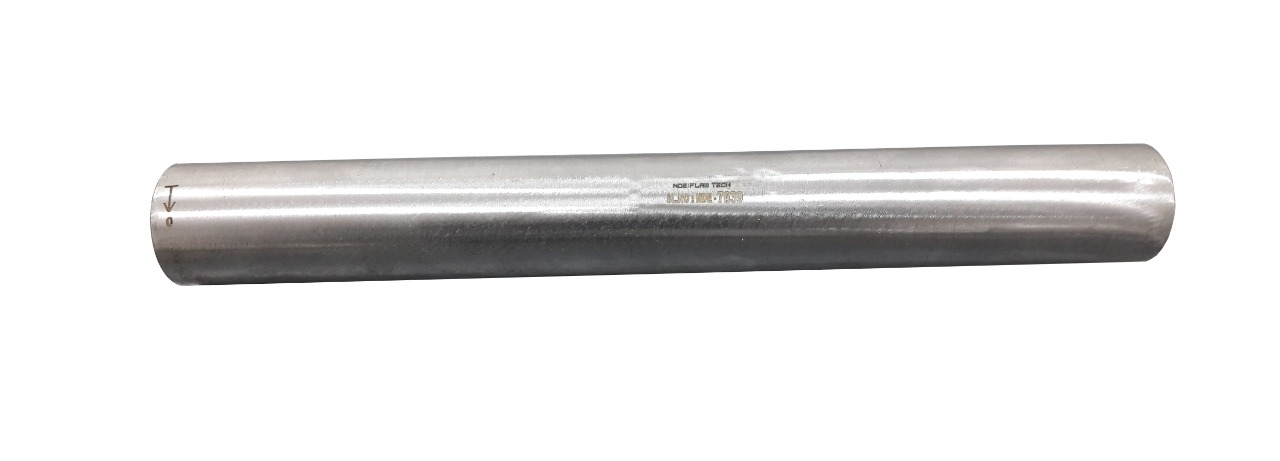

Rod Stock Ultrasonic Test Practical Exam Flawed Specimen (Inch Version) Carbon Steel

Rod Stock Ultrasonic Test Practical Exam Flawed Specimen (Inch Version) Carbon Steel Rod Stock Ultrasonic Test Practical Exam Flawed Specimen Rod & Bar Stock Ultrasonic Practical Exam flawed test specimens. Geometry: 1.5" OD x 12". Flaws: 3, randomly placed Standard Tolerance: +/-0.150" (4mm). Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available.

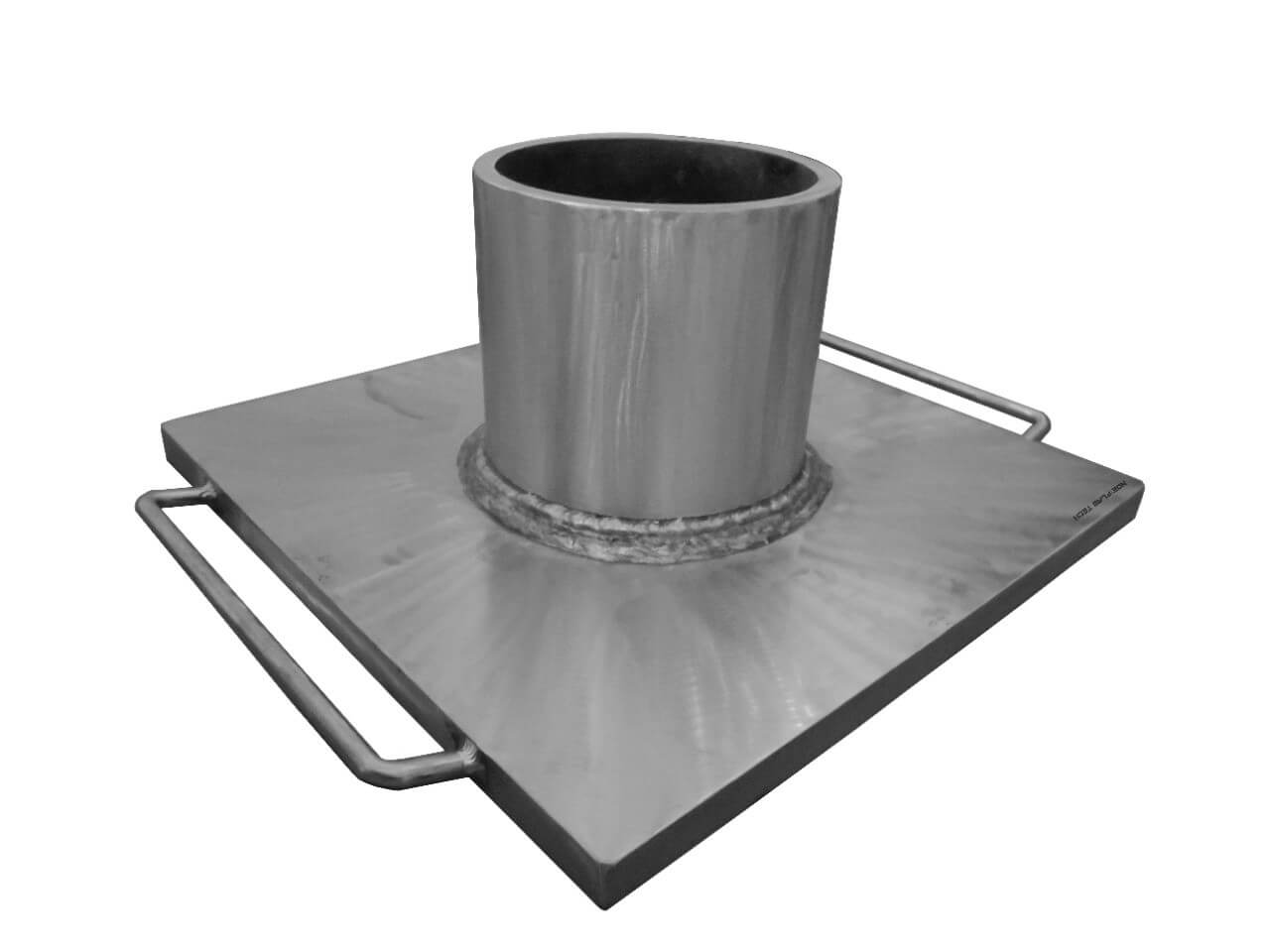

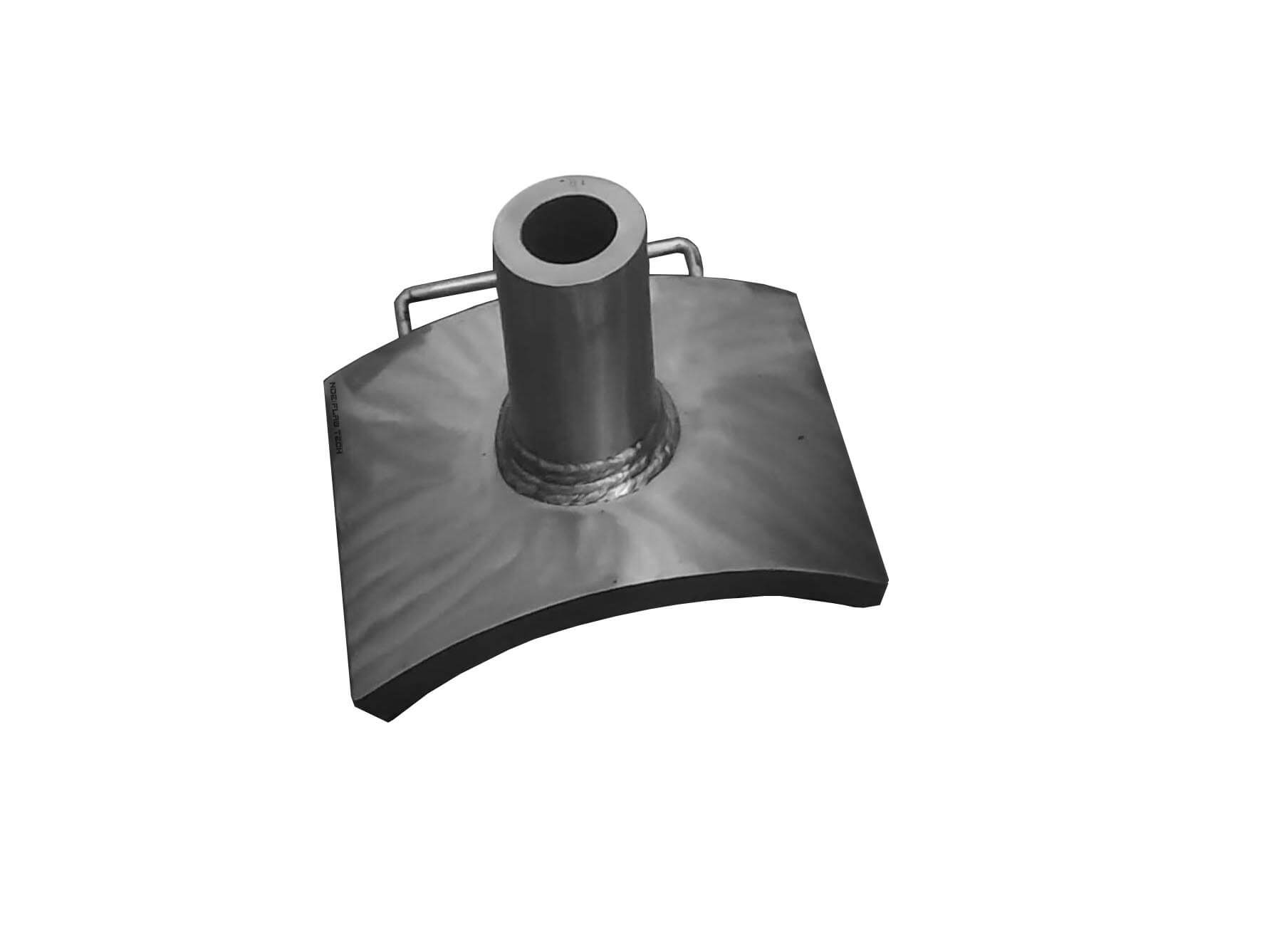

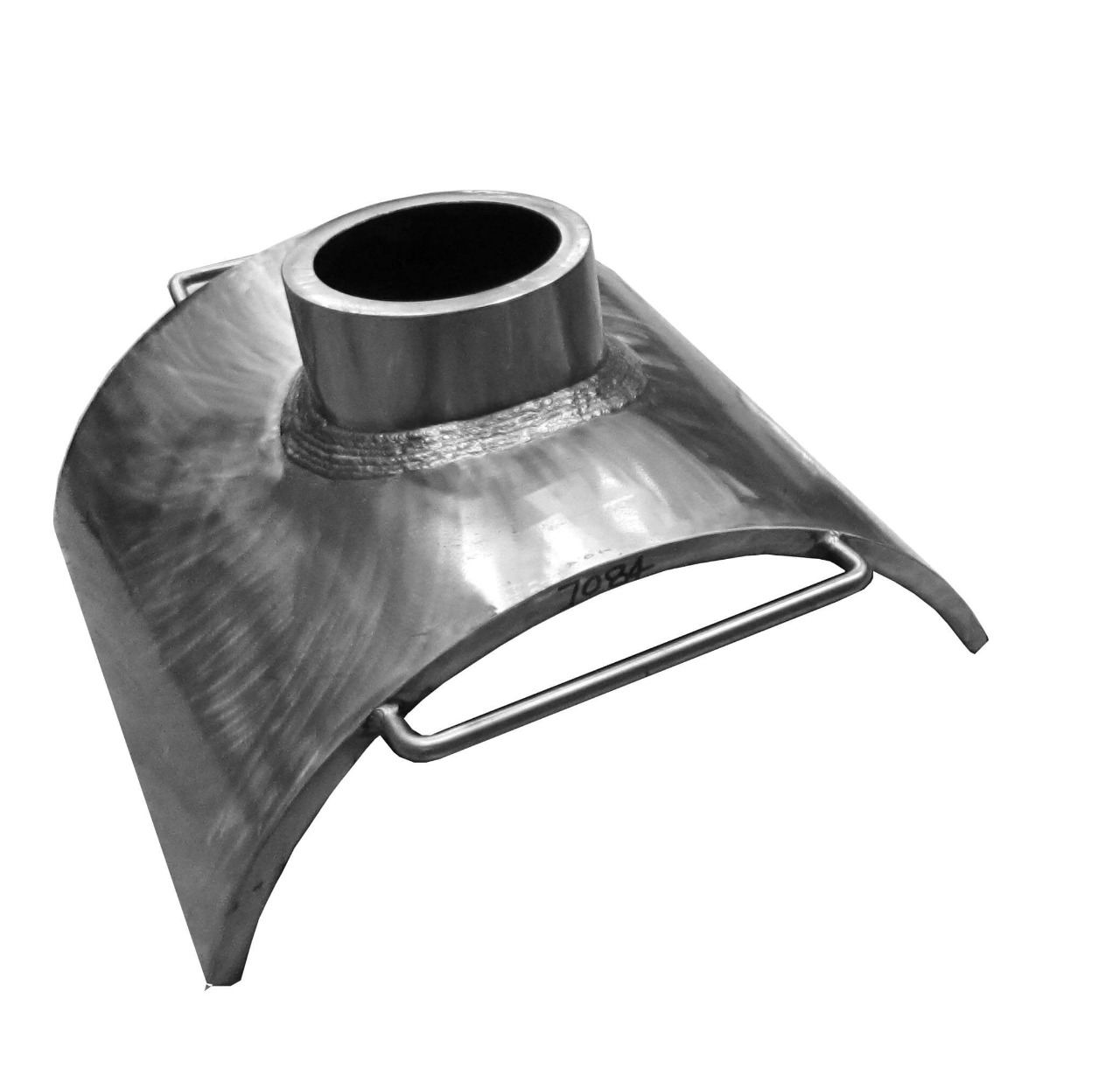

Nozzle to Plate Weld Ultrasonic Test Practical Exam Flaw Specimen (Inch Version) Carbon Steel

Nozzle to Plate Weld Ultrasonic Test Practical Exam Flaw Specimen (Inch Version) Carbon Steel Nozzle to Plate Weld Ultrasonic Test Practical Exam Flaw Specimen Nozzle to Plate Weld Ultrasonic Practical Exam flawed specimens. Geometry: 2" Sch160 (0.35” wall) x 8” (L) pipe to 0.375” (T) x 8" (W) x 8" (L) Plate. Flaws: 3, randomly placed Standard Tolerance: +/-0.150" (4mm). Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available.

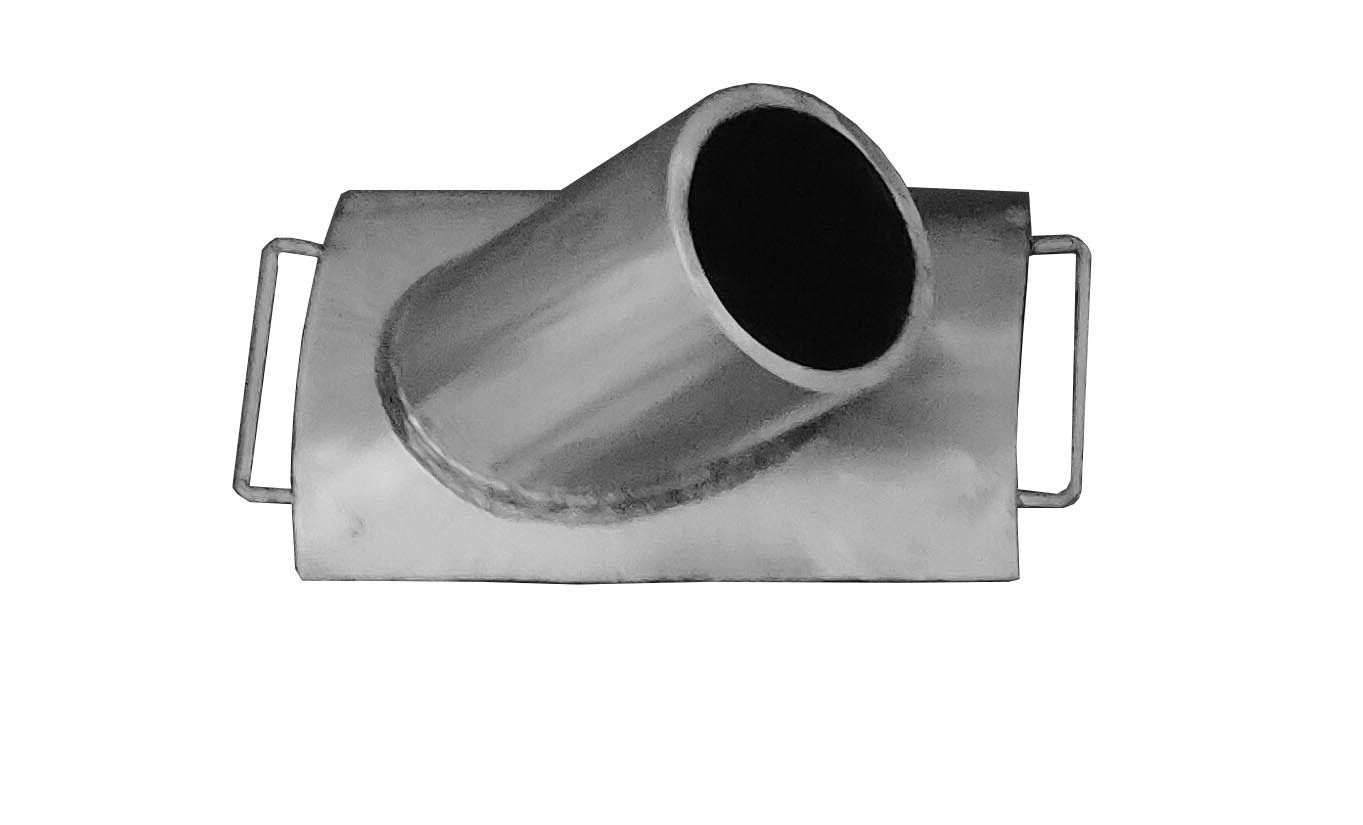

3” Pipe to Nozzle Ultrasonic Test Flawed Specimens Set on Partial Penetration Joint (Inch Version) Carbon Steel

3” Pipe to Nozzle Ultrasonic Test Flawed Specimens Set on Partial Penetration Joint (Inch Version) Carbon Steel 3” Pipe to Nozzle Ultrasonic Test Flawed Specimens 0.6” (Set on Partial Penetration Joint) Geometry: Pipe to Flange Nozzle Joint with Weld length 8” to 10” and Thickness Range 0.6 to 0.8” with (Set On Partial Penetration Joint). Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080" Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

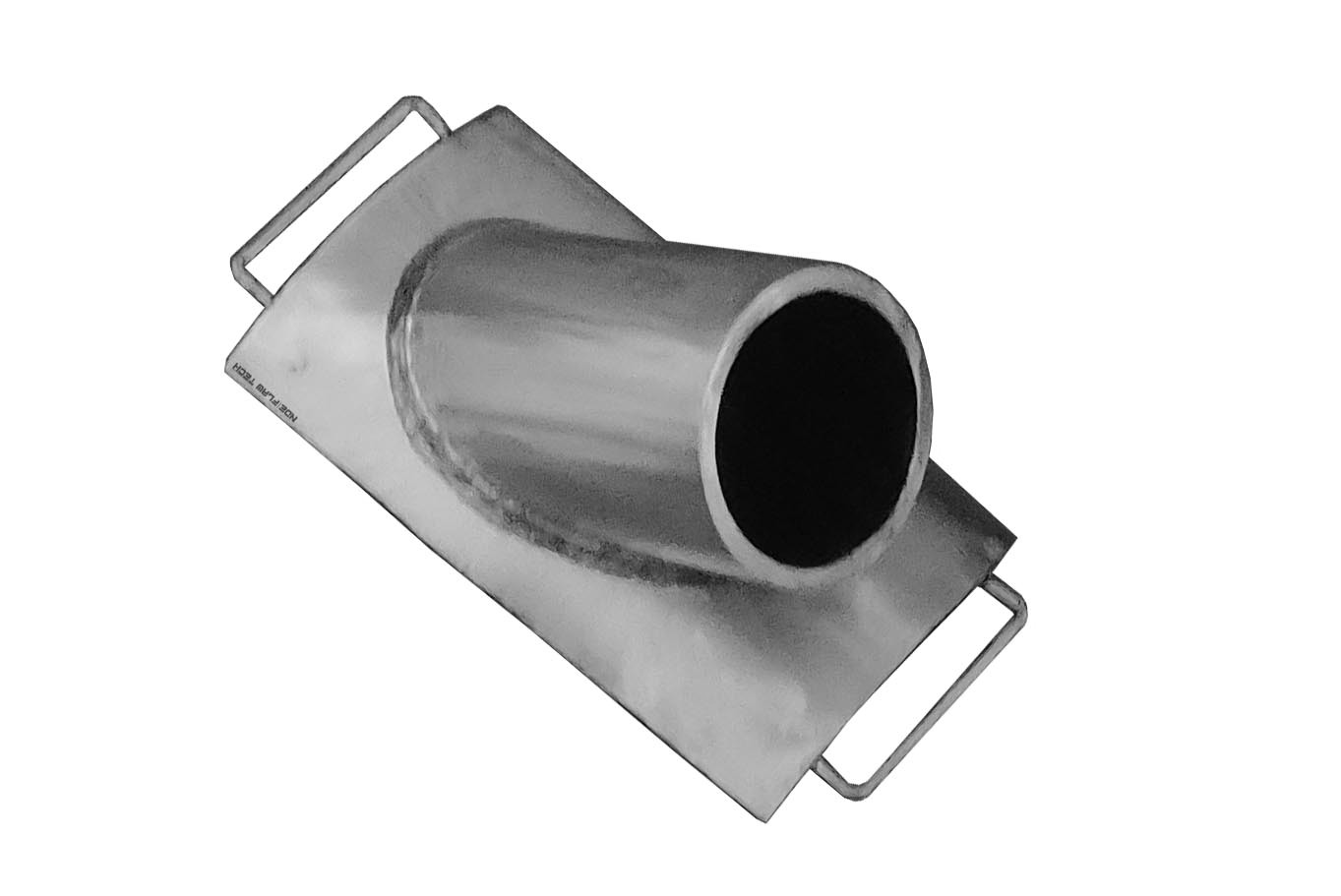

3" Pipe to Nozzle Ultrasonic Test Flaw Specimen Set On Full Penetration (Inch Version) Carbon Steel

3" Pipe to Nozzle Ultrasonic Test Flaw Specimen Set On Full Penetration (Inch Version) Carbon Steel 3" Pipe to Nozzle Ultrasonic Test Flaw Specimen 0.6” (Set On Full Penetration) Geometry: Pipe to Flange Nozzle Joint with Weld length 8” to 10” mm and Thickness Range 0.6” to 0.8” mm with (Set On Full Penetration Joint) Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 per specimen, randomly placed Specimen Tolerance: +/- 0.080" Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

8" Pipe to Nozzle UT Flaw Test Specimens Set on Partial Penetration Joint (Inch Version) Carbon Steel

8" Pipe to Nozzle UT Flaw Test Specimens Set on Partial Penetration Joint (Inch Version) Carbon Steel 8" Pipe to Nozzle UT Ultrasonic Flaw Test Specimens 0.8” (Set on Partial Penetration Joint) Geometry: Pipe to Flange Nozzle Joint with weld length above 24” Main Pipe Segment 24” Dia. Branch 8” Dia. Thickness 0.8” with Set On Partial Penetration Joint. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080". Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

Ø8" Pipe to Nozzle UT Flaw Test Specimens Set On Full Penetration Joint (Inch Version) Carbon Steel

Ø8" Pipe to Nozzle UT Flaw Test Specimens Set On Full Penetration Joint (Inch Version) Carbon Steel Ø8"Pipe to Nozzle UT (Ultrasonic) Flaw Test Specimens 0.8” (Set On Full Penetration Joint) Geometry: Pipe to Flange Nozzle Joint with weld length above 24” Main Pipe Segment Ø24” Dia. Branch Ø8” Dia. Thickness 0.8” with (Set On Full Penetration Joint). Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080". Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

3" Pipe to Nozzle Ultrasonic Test Flaw Specimen Set Through Partial Penetration Joint (Inch Version) Carbon Steel

3" Pipe to Nozzle Ultrasonic Test Flaw Specimen Set Through Partial Penetration Joint (Inch Version) Carbon Steel 3" Pipe to Nozzle Ultrasonic Test Flaw Specimen 0.6” (Set Through Partial Penetration Joint) Geometry: Pipe to Flange Nozzle Joint with Weld length 8” to 10” and Thickness Range 0.6” to 0.8” with (Set Through Partial Penetration Joint) Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080". Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

Ø3" Pipe to Nozzle Ultrasonic Test Flawed Specimens Set through Full Penetration (Inch Version) Carbon Steel

Ø3" Pipe to Nozzle Ultrasonic Test Flawed Specimens Set through Full Penetration (Inch Version) Carbon Steel Ø3" Pipe to Nozzle Ultrasonic Test Flawed Specimens 0.6” (Set through Full Penetration) Geometry: Pipe to Flange Nozzle Joint with Weld length 8” to 10” and Thickness Range 0.6” to 0.8” with (Set Through Full Penetration Joint) Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080". Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

Ø8" Pipe to Nozzle Weld UT Flaw Specimens Set Through Partial Penetration Joint (Inch Version) Carbon Steel

Ø8" Pipe to Nozzle Weld UT Flaw Specimens Set Through Partial Penetration Joint (Inch Version) Carbon Steel Ø8"Pipe to Nozzle Weld UT Flaw Specimens 0.8” (Set Through Partial Penetration Joint) Geometry: Pipe to Flange Nozzle Joint with weld length above 24” Main Pipe Segment Ø24” Dia. Branch Ø8” Dia. Thickness 0.8” with (Set Through) Partial Penetration Joint. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080" Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

Ø8" Pipe to Nozzle Weld UT Flaw Specimen Set Through Full Penetration Joint (Inch Version) Carbon Steel

Ø8" Pipe to Nozzle Weld UT Flaw Specimen Set Through Full Penetration Joint (Inch Version) Carbon Steel Ø8"Pipe to Nozzle Weld UT Flaw Specimen 0.8” (Set Through Full Penetration Joint) Geometry: Pipe to Flange Nozzle Joint with weld length 24” Main Pipe Segment Ø24” Dia. Branch Ø8” Dia. Thickness 0.8” with (Set Through) Full Penetration Joint. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080". Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

30ᵒ Tubular Nodes Weld UT Flaw Test Specimen (Inch Version) Carbon Steel

30ᵒ Tubular Nodes Weld UT Flaw Test Specimen (Inch Version) Carbon Steel 30ᵒ Tubular Nodes Weld UT Flaw Test Specimen 0.5” to 0.8” (Ultrasonic Test) Tubular Nodes 0.5” to 0.8” 30ᵒ UT Flawed Specimens Geometry: Tubular Nodes Dihedral Angle 30ᵒ Main Pipe Segment Ø20” Dia. 0.8” to 1.0” WT & Branch Ø8” Dia. And 0.5” to 0.8” WT. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080". Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

35ᵒ Tubular Nodes Weld UT Flaw Test Specimen (Inch Version)

35ᵒ Tubular Nodes Weld UT Flaw Test Specimen (Inch Version) 35ᵒ Tubular Nodes Weld UT Flaw Test Specimen 0.5” to 0.8” (Ultrasonic Test) Tubular Nodes 0.5” to 0.8” 35ᵒ UT Flawed Specimens Geometry: Tubular Nodes Dihedral Angle 35ᵒ Main Pipe Segment Ø20” Dia. 0.8” to 1.0” WT & Branch Ø8” Dia. And 0.5” to 0.8” WT. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080". Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

40ᵒ Tubular Nodes Weld UT Flaw Test Specimen (Inch Version)

40ᵒ Tubular Nodes Weld UT Flaw Test Specimen (Inch Version) 40ᵒ Tubular Nodes Weld UT Flaw Test Specimen 0.5” to 0.8” (Ultrasonic Test) Tubular Nodes 0.5” to 0.8” 40ᵒ UT Flawed Specimens Geometry: Tubular Nodes Dihedral Angle 40ᵒ Main Pipe Segment Ø20” Dia. 0.8” to 1.0” WT & Branch Ø8” Dia. And 0.5” to 0.8” WT. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080". Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

45ᵒ Tubular Nodes Weld UT Flaw Test Specimen (Inch Version)

45ᵒ Tubular Nodes Weld UT Flaw Test Specimen (Inch Version) 45ᵒ Tubular Nodes Weld UT Flaw Test Specimen 0.5” to 0.8” (Ultrasonic Test) Tubular Nodes 0.5” to 0.8” 45ᵒ UT Flawed Specimens Geometry: Tubular Nodes Dihedral Angle 45ᵒ Main Pipe Segment Ø20” Dia. 0.8” to 1.0” WT & Branch Ø8” Dia. And 0.5” to 0.8” WT. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080". Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

60ᵒ Tubular Nodes Weld UT Flaw Test Specimen (Inch Version) Carbon Steel

60ᵒ Tubular Nodes Weld UT Flaw Test Specimen (Inch Version) Carbon Steel 60ᵒ Tubular Nodes Weld UT Flaw Test Specimen 0.5” to 0.8” (Ultrasonic Test) Tubular Nodes 0.5” to 0.8” 60ᵒ UT Flawed Specimens Geometry: Tubular Nodes Dihedral Angle 60ᵒ Main Pipe Segment Ø20” Dia. 0.8” to 1.0” WT & Branch Ø8” Dia. And 0.5” to 0.8” WT. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080". Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.

70ᵒ Tubular Nodes Weld UT Flaw Test Specimen (Inch Version)

70ᵒ Tubular Nodes Weld UT Flaw Test Specimen (Inch Version) 70ᵒ Tubular Nodes Weld UT Flaw Test Specimen 0.5” to 0.8” (Ultrasonic Test) Tubular Nodes 0.5” to 0.8” 70ᵒ UT Flawed Specimens Geometry: Tubular Nodes Dihedral Angle 70ᵒ Main Pipe Segment Ø20” Dia. 0.8” to 1.0” WT & Branch Ø8” Dia. And 0.5” to 0.8” WT. Material: Carbon Steel. Customized Calibration Test Block and Flaw Specimen also available. Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080". Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets.