API CORROSION/EROSION 100mm Pipe (Metric Version)

API CORROSION/EROSION 100mm Pipe (Metric Version) Material: Carbon Steel pipe, • 100mm OD with variable schedules at Sch10 (4mm), Sch80 (8.5mm) and Sch160 (12.5mm) • The pipe is a cut 180° segment with 300mm arc length. • The ID has 3 machined steps; 4mm, 8.5mm and 12.5mm, each step is 100mm in axial length. Specifications: • Each wall thickness/step will contain 1 or 2 ID surface indications. • The indications include: • Corrosion • Random Pitting • Erosion • The indication depths will vary depending on the pipe wall thickness. • Typical depths range from 25%, 50% and 75% through wall. • The overall size of the surface indication will vary as to the depth of the indication. • The indication depth will be stated at the deepest point of each indication. Pitting indications will be based on the deepest pit. Final Documentation: • Includes C of C, “As Built” CAD and Measuring & Test Equipment Certificate • “As Built” CAD will show a general description of the flaws surface area.

API CORROSION/EROSION 150mm Pipe (Metric Version)

API CORROSION/EROSION 150mm Pipe (Metric Version) Material: Carbon Steel pipe • 168mm OD with variable schedules at Sch STD (7mm), Sch80 (11mm) and Sch120 (12.5mm) • The pipe is a cut 180° segment with 300mm arc length. • The ID has 3 machined steps; 7mm, 11mm and 12.5, each step is 100mm in axial length. Specifications: • Each wall thickness/step will contain 1 or 2 ID surface indications. • The indications include: • Corrosion • Random Pitting • Erosion • The indication depths will vary depending on the pipe wall thickness. • Typical depths range from 25%, 50% and 75% through wall. • The overall size of the surface indication will vary as to the depth of the indication. • The indication depth will be stated at the deepest point of each indication. Pitting indications will be based on the deepest pit. Final Documentation: • Includes C of C, “As Built” CAD and Measuring & Test Equipment Certificates • “As Built” CAD will show a general description of the flaws surface area.

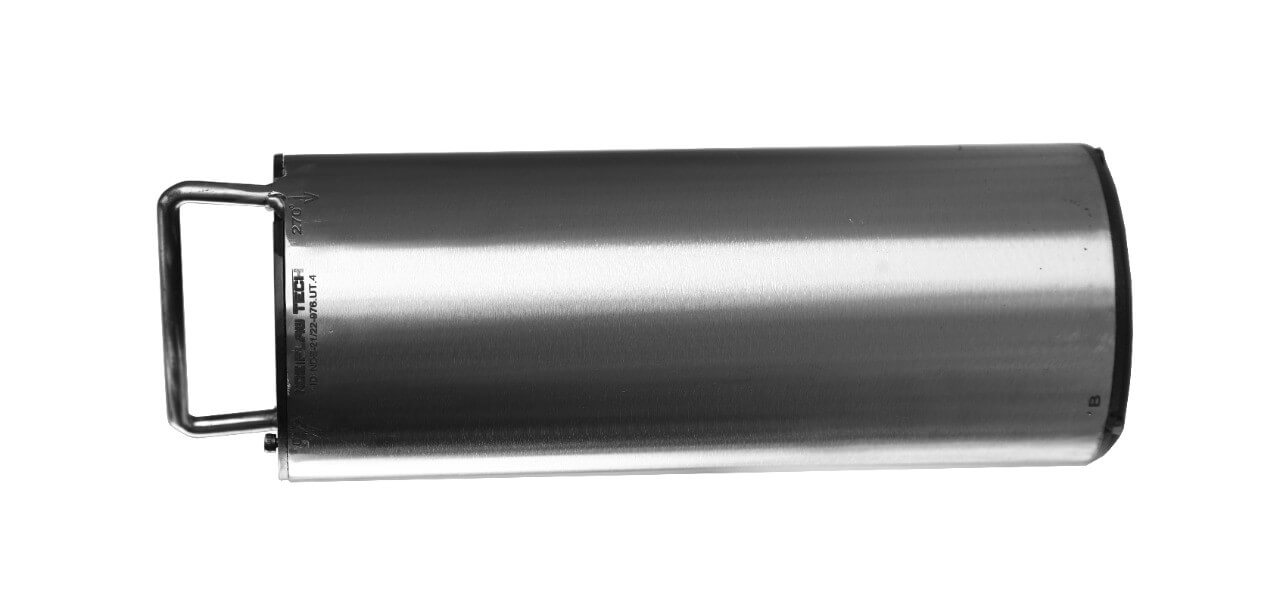

API CORROSION/EROSION 200mm Pipe (Metric Version)

API CORROSION/EROSION 200mm Pipe (Metric Version) Material: Carbon Steel pipe • 219mm OD with variable schedules at Sch STD (8mm), Sch80 (12.5mm) and Sch120 (18mm) • The pipe is a cut 180° segment with 300mm arc length. • The ID has 3 machined steps; 8mm, 12.5mm and 18, each step is 100mm in axial length. Specifications: • Each wall thickness/step will contain 1 or 2 ID surface indications. • The indications include: • Corrosion • Random Pitting • Erosion • The indication depths will vary depending on the pipe wall thickness. • Typical depths range from 25%, 50% and 75% through wall. • The overall size of the surface indication will vary as to the depth of the indication. • The indication depth will be stated at the deepest point of each indication. Pitting indications will be based on the deepest pit. Final Documentation: • Includes C of C, “As Built” CAD and Measuring & Test Equipment Certificates • “As Built” CAD will show a general description of the flaws surface area.

API CORROSION/EROSION 300mm Pipe (Metric Version)

API CORROSION/EROSION 300mm Pipe (Metric Version) Material: Carbon Steel pipe • 324mm OD with variable schedules at Sch STD (9.5mm), Sch80 (17.5mm) and Sch120 (25mm) • The pipe is a cut 180° segment with 300mm arc length. • The ID has 3 machined steps; 9.5mm, 17.5mm and 25 each step is 100mm in axial length. Specifications: • Each wall thickness/step will contain 1 or 2 ID surface indications. • The indications include: • Corrosion • Random Pitting • Erosion • The indication depths will vary depending on the pipe wall thickness. • Typical depths range from 25%, 50% and 75% through wall. • The overall size of the surface indication will vary as to the depth of the indication. • The indication depth will be stated at the deepest point of each indication. Pitting indications will be based on the deepest pit. Final Documentation: • Includes C of C, “As Built” CAD and Measuring & Test Equipment Certificates • “As Built” CAD will show a general description of the flaws surface area.