PAUT And TOFD Pipe to Pipe Weld Joint Flawed Specimen 10" Dia (Inch Version) Carbon Steel

PAUT And TOFD Pipe to Pipe Weld Joint Flawed Specimen 10" Dia (Inch Version) Carbon Steel PAUT And TOFD Pipe to Pipe Weld Joint Flawed Specimen 10" Dia Phased Array Ultrasonic Testing (PAUT)-Weld Joint Flawed Specimen 10" Dia- Time-of-flight diffraction ultrasonics Geometry: Pipe to Pipe Butt Weld Joint with Pipe 10" Dia. And 8” Wide on Either Side of The Weld thickness range >0.8” to 1.2” (Carbon Steel) Material: Carbon Steel Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080" Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Customized Calibration Test Block and Flaw Specimen also available.

PAUT and TOFD Pipe to Pipe Weld Joint Flawed Specimen 16" Dia (Inch Version) Carbon Steel

PAUT and TOFD Pipe to Pipe Weld Joint Flawed Specimen 16" Dia Inch Version Carbon Steel PAUT and TOFD Pipe to Pipe Weld Joint Flawed Specimen 16" Dia Time-of-flight diffraction ultrasonic (TOFD)-Weld Joint Flawed Specimen 16" Dia- Phased Array Ultrasonic Testing (PAUT) Geometry: PAUT And TOFD Pipe Butt Weld Joint 16" Dia Flawed Specimens Pipe to Pipe Butt Weld Joint with Pipe 16" Dia And 10” Wide on Either Side of The Weld thickness range >1” to 2” (Carbon Steel) Material: Carbon Steel Flaws: 3 or 4 per specimen, randomly placed Specimen Tolerance: +/- 0.080" Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Customized Calibration Test Block and Flaw Specimen also available.

PAUT And TOFD Plate TO Plate Weld Flawed Specimen Double V 1.2” (Inch Version) Carbon Steel

PAUT And TOFD Plate TO Plate Weld Flawed Specimen Double V 1.2” (Inch Version) Carbon Steel PAUT And TOFD Plate TO Plate Weld Flawed Specimen Double V ASYMMETRICAL 1/3+2/3 THK Time-of-flight diffraction ultrasonic (TOFD)-PLATE Weld Joint Flawed Specimen-Phased Array Ultrasonic Testing (PAUT) Geometry: Plate to Plate Double V Butt Weld 16” Long and 8” Wide on Either Side of The Weld thickness range > 0.8” to 1.2” (Carbon Steel) ASYMMETRICAL 1/3+2/3 thickness. Material: Carbon Steel Flaws: 3 per specimen, randomly placed Specimen Tolerance: +/- 0.080" Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Customized Calibration Test Block and Flaw Specimen also available.

PAUT And TOFD Plate TO Plate Weld Flawed Specimen Double V 2” (Inch Version) Carbon Steel

PAUT And TOFD Plate TO Plate Weld Flawed Specimen Double V 2” (Inch Version) Carbon Steel PAUT And TOFD Plate TO Plate Weld Flawed Specimen Double V ASYMMETRICAL 1/3+2/3 THK Time-of-flight diffraction ultrasonic (TOFD)-PLATE Weld Joint Flawed Specimen-Phased Array Ultrasonic Testing (PAUT) Geometry: Plate to Plate Double V Butt Weld 20” Long and 10” Wide on Either Side of The Weld thickness range > 1.2” to 2” (Carbon Steel) ASYMMETRICAL 1/3+2/3 thickness. Material: Carbon Steel Flaws: 3 per specimen, randomly placed Specimen Tolerance: +/- 0.080" Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Customized Calibration Test Block and Flaw Specimen also available.

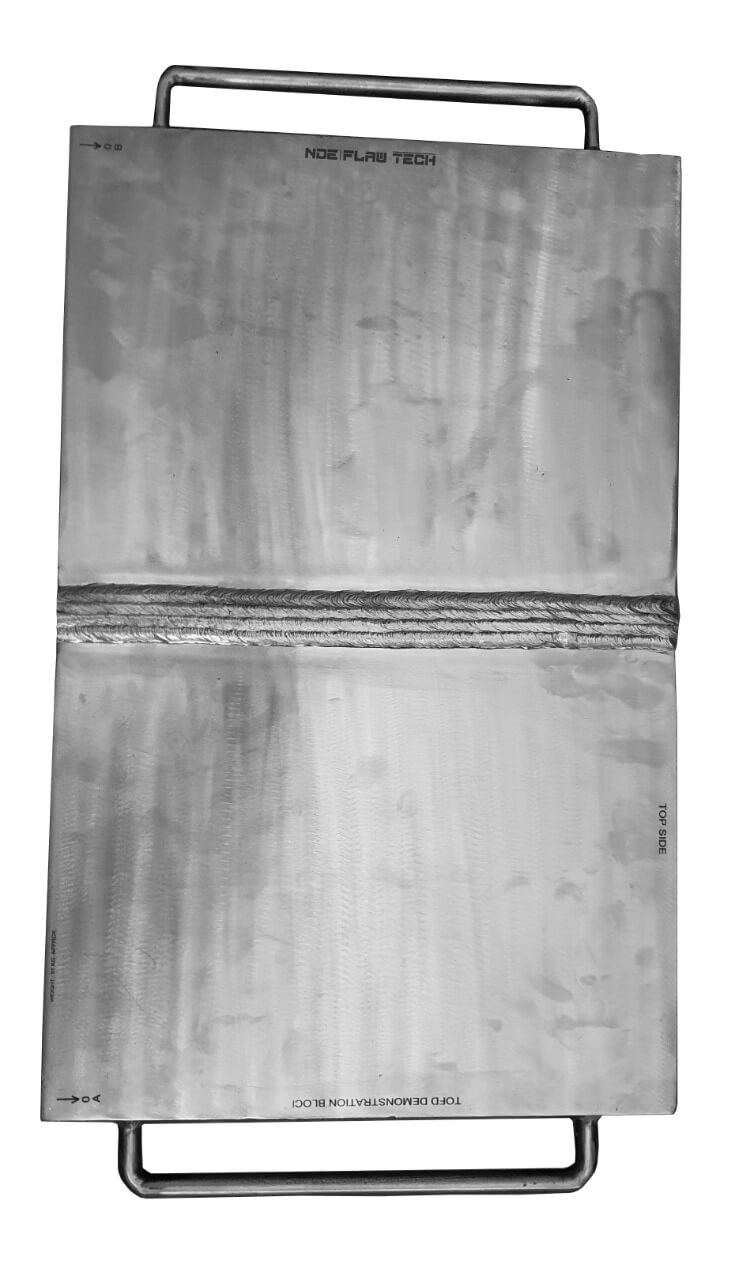

PAUT And TOFD Plate to Plate Single V Flawed Specimens 1.2” (Inch Version) Carbon Steel

PAUT And TOFD Plate to Plate Single V Flawed Specimens 1.2” (Inch Version) Carbon Steel PAUT And TOFD Plate to Plate Single V Flawed Specimens ASYMMETRICAL 1/3+2/3 THK Phased Array Ultrasonic Testing (PAUT) - Plate to Plate Single V Flawed Specimens-Time-of-flight diffraction ultrasonic Geometry: Plate to Plate Double V Butt Weld 16” Long and 8” Wide on Either Side of The Weld thickness range > 0.8” to 1.2” Carbon Steel ASYMMETRICAL1/3+2/3 thickness. Material: Carbon Steel. Flaws: 3 per specimen, randomly placed Specimen Tolerance: +/- 0.080" Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Customized Calibration Test Block and Flaw Specimen also available.

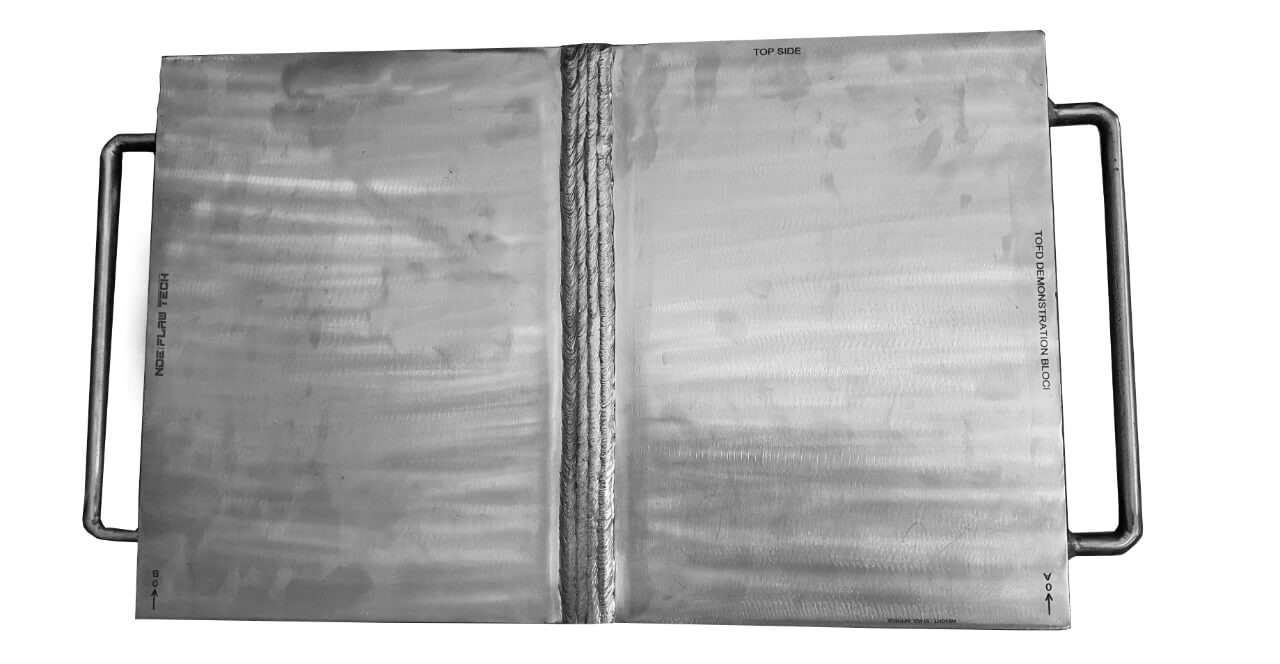

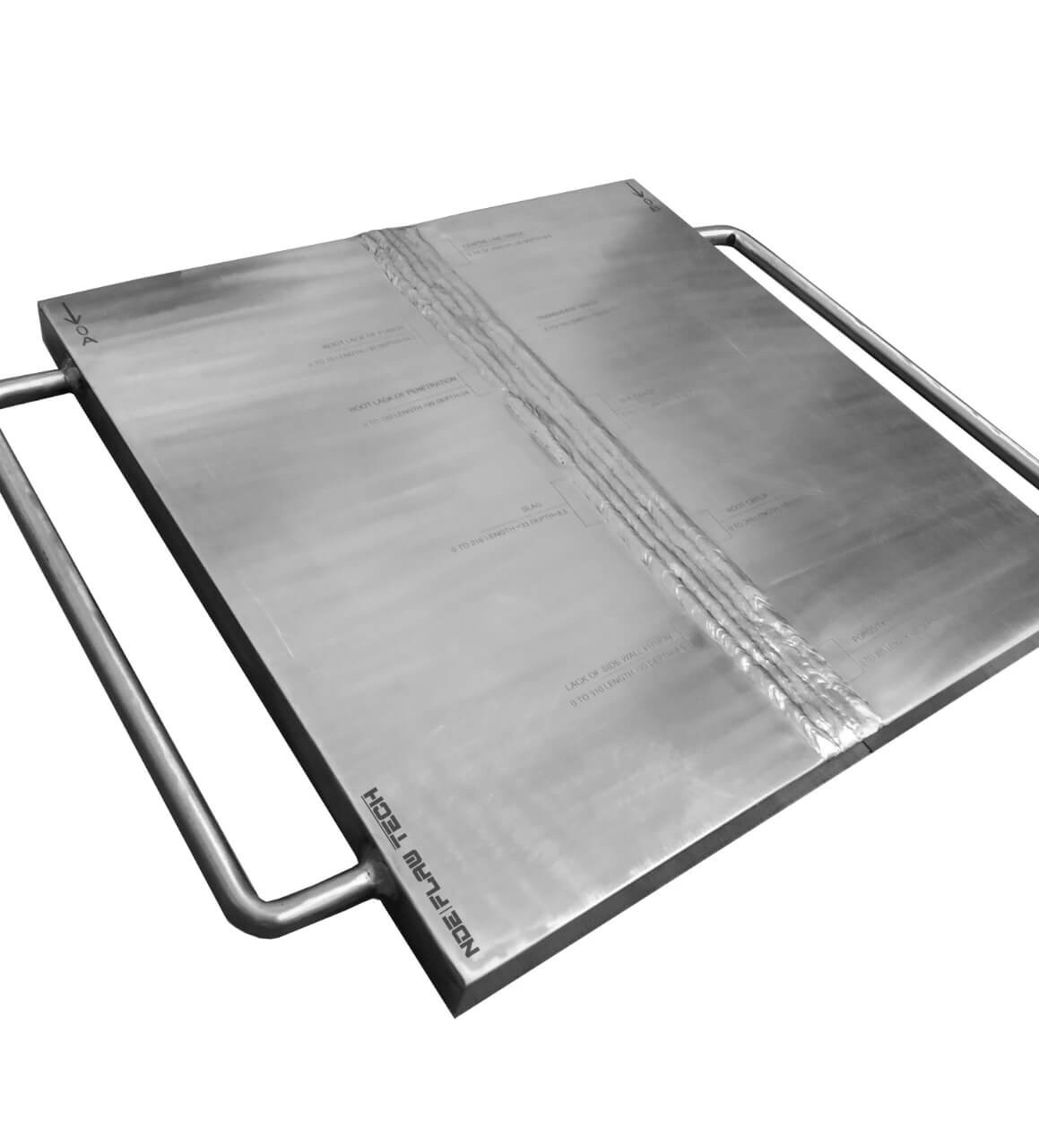

PAUT And TOFD Plate to Plate Single V Flawed Specimens 2” (Inch Version) Carbon Steel

PAUT And TOFD Plate to Plate Single V Flawed Specimens 2” (Inch Version) Carbon Steel PAUT And TOFD Plate to Plate Single V Flawed Specimens ASYMMETRICAL 1/3+2/3 THK Phased Array Ultrasonic Testing (PAUT) - Plate to Plate Single V Flawed Specimens-Time-of-flight diffraction ultrasonic Geometry: Plate to Plate Double V Butt Weld 20” Long and 10” Wide on Either Side of The Weld thickness range > 1.2” to 2” Carbon Steel ASYMMETRICAL1/3+2/3 thickness. Material: Carbon Steel. Flaws: 3 per specimen, randomly placed Specimen Tolerance: +/- 0.080" Documentation: NDT Verification Reports, C of C, CAD Drawings and Test Sheets. Customized Calibration Test Block and Flaw Specimen also available.