ISO 9712 UT TRAINING KIT

ISO 9712 UT TRAINING KIT ISO 9712 Ultrasonic testing training kit contains 8 specimens, Include 5 plates and 3 pipe. Specimen: (1)Single V plate – 12” (L) x 6” (W) on Either Side of The Weld thickness x 0.6” (T) (1)Single V plate – 12” (L) x 6” (W) on Either Side of The Weld thickness x 0.8” (T) (1)Single V plate – 12” (L) x 6” (W) on Either Side of The Weld thickness x 1.0” (T) (1)Double V plate – 12” (L) x 6” (W) on Either Side of The Weld thickness x 0.8” (T) (1)Double V plate – 12” (L) x 6” (W) on Either Side of The Weld thickness x 1.0” (T) (1)Single V Pipe – Ø3” sch160 (0.4”) x 6” (L) on Either Side of The Weld thickness (1)Single V Pipe – Ø4” sch160 (0.5”) x 6” (L) on Either Side of The Weld thickness (1)Single V Pipe – Ø6” sch160 (0.7”) x 6” (L) on Either Side of The Weld thickness

ISO 9712 RT TRAINING KIT

ISO 9712 RT TRAINING KIT ISO 9712 Radiography testing training kit contains 8 specimens, Include 5 plates and 3 pipe. Specimen: (1)Single V plate – 12” (L) x 6” (W) on Either Side of The Weld thickness x 0.6” (T) (1)Single V plate – 12” (L) x 6” (W) on Either Side of The Weld thickness x 0.8” (T) (1)Single V plate – 12” (L) x 6” (W) on Either Side of The Weld thickness x 1.0” (T) (1)Double V plate – 12” (L) x 6” (W) on Either Side of The Weld thickness x 0.8” (T) (1)Double V plate – 12” (L) x 6” (W) on Either Side of The Weld thickness x 1.0” (T) (1)Single V Pipe – Ø3” sch160 (0.4”) x 6” (L) on Either Side of The Weld thickness (1)Single V Pipe – Ø4” sch160 (0.5”) x 6” (L) on Either Side of The Weld thickness (1)Single V Pipe – Ø6” sch160 (0.7”) x 6” (L) on Either Side of The Weld thickness

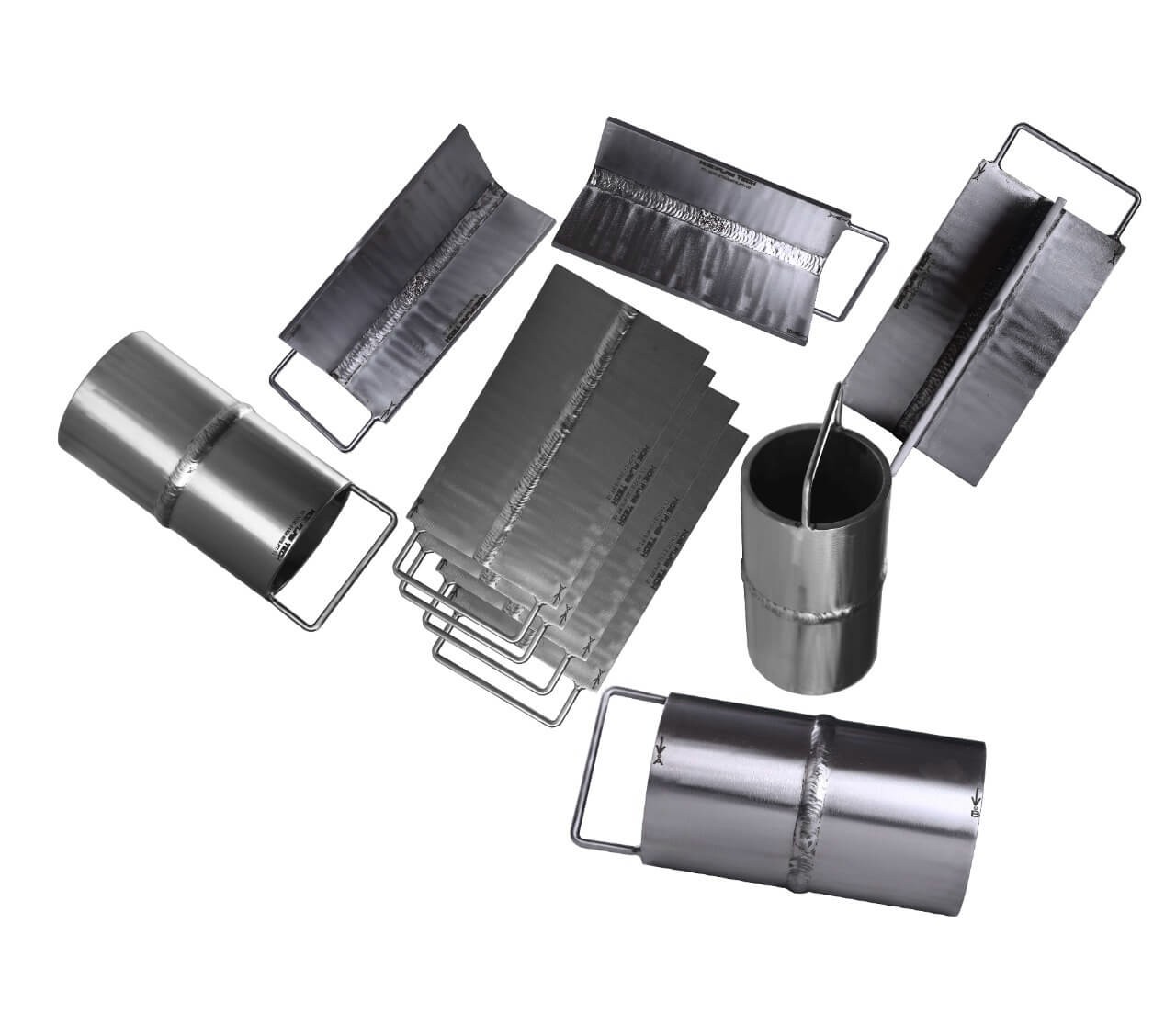

ISO 9712 MT TRAINING KIT

ISO 9712 MT TRAINING KIT ISO 9712 Magnetic Particle testing training kit contains 10 specimens, Include 4 plates, 3 pipe and 3 T-plate. Flaws include surface flaw and near surface flaws. Specimen Details: (4)Plate to Plate – 10” (L) x 3” (W) on each side of the weld x 0.25” (T). (3)Pipe to Pipe - Ø4” sch40 (0.25” wall) x 4” Long on either side of the weld (3)T-plate – 10” (L) x 6” Base x 4” Wide x 0.25” (T).

ISO 9712 PT TRAINING KIT

ISO 9712 PT TRAINING KIT ISO 9712 Penetrant testing training kit contains 10 specimens, Include 4 plates, 3 pipe and 3 T-plate. Flaws include surface flaws. Specimen Details: (4)Plate to Plate – 10” (L) x 3” (W) on each side of the weld x 0.25” (T). (3)Pipe to Pipe - Ø4” sch40 (0.25” wall) x 4” Long on either side of the weld (3)T-plate – 10” (L) x 6” Base x 4” Wide x 0.25” (T).

ISO 9712 VT TRAINING KIT

ISO 9712 VT TRAINING KIT ISO 9712 Visual testing training kit contains 10 specimens, Include 4 plates, 3 pipe and 3 T-plate. Flaws include surface flaws. Specimen Details: (4)Plate to Plate – 10” (L) x 3” (W) on each side of the weld x 0.25” (T). (3)Pipe to Pipe - Ø4” sch40 (0.25” wall) x 4” Long on either side of the weld (3)T-plate – 10” (L) x 6” Base x 4” Wide x 0.25” (T).

ISO 9712 ET TRAINING KIT

ISO 9712 ET TRAINING KIT ISO 9712 Eddy Current testing training kit with coated specimen, contains 10 specimens, Include 4 plates, 3 pipe and 3 T-plate. Flaws include surface flaws. Specimen Details: (4)Plate to Plate – 10” (L) x 3” (W) on each side of the weld x 0.25” (T). (3)Pipe to Pipe - Ø4” sch40 (0.25” wall) x 4” Long on either side of the weld (3)T-plate – 10” (L) x 6” Base x 4” Wide x 0.25” (T).

ISO 9712 TKY TRAINING KIT

ISO 9712 TKY TRAINING KIT ISO 9712 TKY training kit, contains 8 specimens, Include 4 T-plates, 2 Node joints and 2 Nozzle joints. Flaws include sub-surface flaws. Specimen Details: • (1) Single V 90° T-Plate Connection- 0.8″ (T) x 12″ (Weld Length) x 8″ (Base) x 8″ (Branch) • (1) Double V 90° T-Plate Connection- 1.0″ (T) x 12″ (Weld Length) x 8″ (Base) x 8″ (Branch) • (1) 45° “Y” Connection- 0.75″ (T) x 12″ (Weld Length) x 4″ (Base) x 8″ (Branch) • (1) 60° “Y” Connection.- 0.75″ (T) x 12″ (Weld Length) x 4″ (Base) x 8″ (Branch) • (1) 30° Node Pipe to Pipe – Branch pipe Ø4” sch 120 (wall thickness – 0.438”) x 6” (L) Base pipe Ø24” sch 60 (180°) x wall thickness 0.968” • (1) 60° Node Pipe to Pipe – Branch pipe Ø4” sch 120 (wall thickness – 0.438”) x 6” (L) Base pipe Ø24” sch 60 (180°) x wall thickness 0.968” • (1) Nozzle Set ON joint – Branch pipe Ø4” sch 120 (wall thickness – 0.438”) x 6” (L) Base pipe Ø24” sch 60 (180°) x wall thickness 0.968” • (1) Nozzle Set Through joint – Branch pipe Ø4” sch 120 (wall thickness – 0.438”) x 6” (L) Base pipe Ø24” sch 60 (180°) x wall thickness 0.968”