3 Notch Eddy Current Standard Test Block

3 Notch Eddy Current Standard test Block Geometry: Dimensions: .250" x 1.0" x 3.0" Contains (3) surface notches at depths of .008", .020", and .040". Notch width typically .004" to .005", with other widths possible

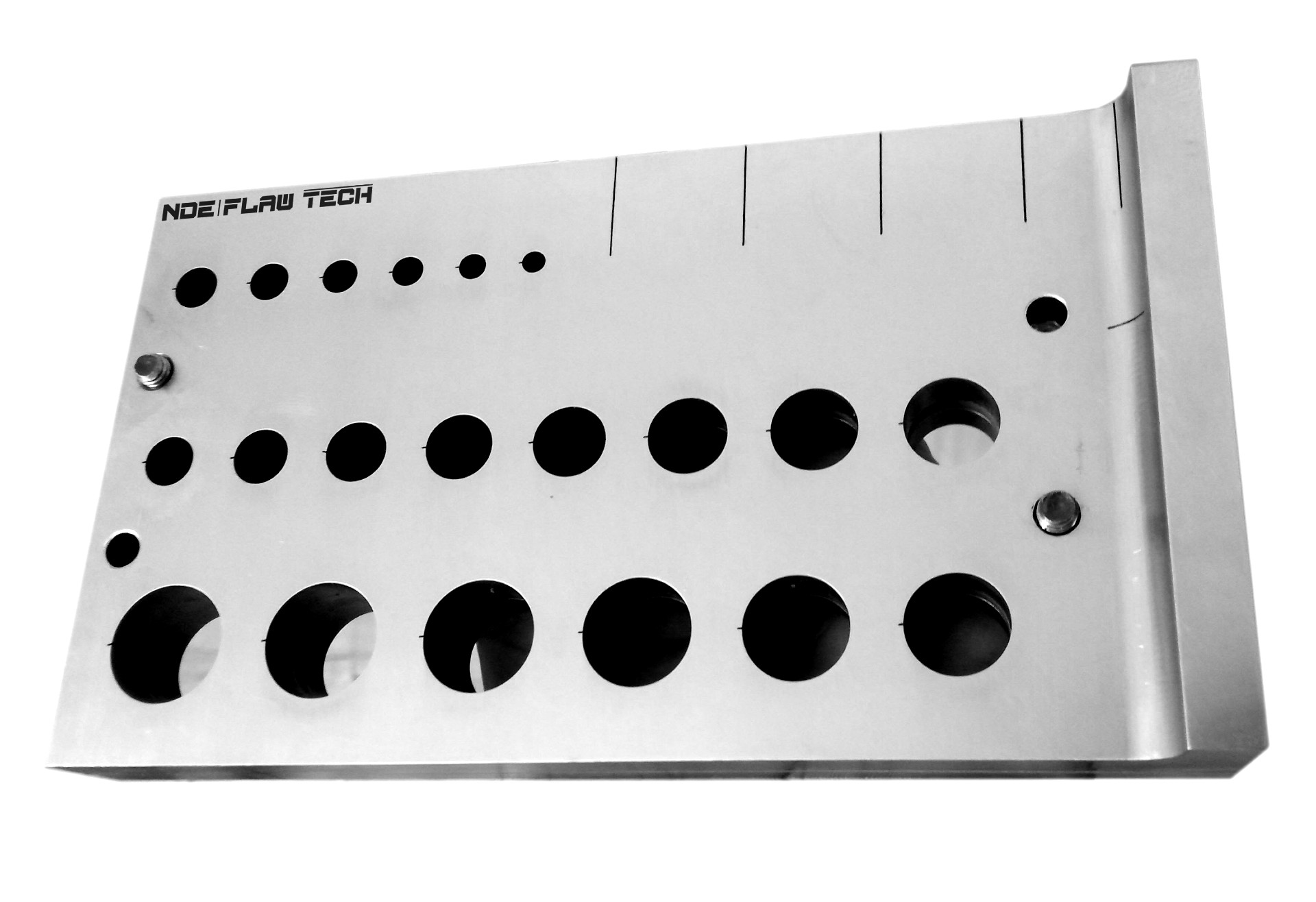

12 Hole 15 Notch General Purpose, Bolt Hole Standard Block

12 Hole 15 Notch General Purpose, Bolt Hole Standard Block Geometry: Block Sizes: 0.25" thick x 2.5" x 6.0" Holes: • 3/16", 7/32", 1/4", 9/32", 5/16", 11/32", 3/8", 7/16", 1/2", 9/16", 5/8" and 3/4" diameter Surface Notches: • Qty 3 @ .008", .020" and .040" deep x 1.0" long Notch Width (All): .004" (± .001) Hole Notch Configurations: • (1).030" x .030" (45°) corner notch @ .004" wide in each hole (Qty 12) • (1).020" full-bore (thru) notch @ .004" wide in each hole - (Qty 12) • (1)Full-bore (thru) notch @ .020" deep x .004" wide and • (1).030" x .030" (45°) corner notch @ .004" in each hole, 180° apart (Qty 24) • (1)Mid-bore notch @ .030" deep x .004" wide x .060" long in each hole - (Qty 12).

DAC GSET Eddy Current Standard Test Block

DAC GSET Eddy Current Standard Test Block Geometry: Overall dimensions: .250/.625" thick x 2.000" wide x 6.375" long Bare Contains: (2) fastener holes, (11) EDM notches, (1) end with a .250" radius Manufactured IAW McDonnell Douglas NDT Manual 06-20-01, Pages F1 to F3, Figure 1.

MIL STD 271F Performance Verification Reference Test Block

MIL STD 271F Performance Verification Reference Test Block Perform instrument verification test using performance verification block. This test shall produce a useable response for both audio and meter outputs or oscilloscope display, as applicable. MIL STD 271F Performance Verification Reference Test Block (Alloy) Geometry: Overall dimensions: 3/8" thick x 4.0" wide x 6.0" long Bare Contains: (4) EDM notches @ .015" deep x .010" max wide x .250" long Manufactured IAW MIL-STD-271F, Paragraph 7.4.2.

Navy Eddy Current Standard Test Block

Navy Eddy Current Standard Test Block The Air Force general purpose eddy current standard (Figure 4-55, Sheet 1 through Figure 4-55, Sheet 3) SHALL be the common standard used to perform ET’s on components within the Air Force. The standard made to the Navy configuration (Figure 4-56) may be used as a substitute for the Air Force general purpose eddy current standard. When using the Navy standard, calibrate on the long EDM notches for surface inspections and the corner notches in the upper layers for bolt hole inspections unless otherwise directed by a part specific procedure. Navy Universal Eddy Current Standard. A (3) plate assembly containing (20) fastener holes with a total of (71) EDM notches in various locations. Overall Dimensions: .875 inch thick x 4.0inch wide x 7.0inch long (20) Fastener Holes from .156 to .750 inch diameter. (40) Corner notches, (20) Bore notches, (9) Surface notches, (1) Tapered notch, (1) Radius notch

USAF General Purpose Eddy Current Standard Test Block

USAF General Purpose Eddy Current Standard Test Block The Air Force general purpose eddy current standard (Figure 4-55, Sheet 1 through Figure 4-55, Sheet 3) SHALL be the common standard used to perform ET’s on components within the Air Force. The standard made to the Navy configuration (Figure 4-56) may be used as a substitute for the Air Force general purpose eddy current standard. When using the Navy standard, calibrate on the long EDM notches for surface inspections and the corner notches in the upper layers for bolt hole inspections unless otherwise directed by a part specific procedure. Manufactured IAW U.S.A.F. Tech Order 33B-1-1, Figure 4-39. NSN 6635-01-092-5129 and P/N 7947479-10. U.S. Air Force General Purpose Eddy Current Standard. A (3) plate assembly containing (20) fastener holes with a total of (66) EDM notches in various locations. • Overall Dimensions: 1.06" thick x 4.0" wide x 7.0" long. • (20) Fastener Holes from .156 to .750" diameter. • (40) Corner notches, (20) Bore notches, (4) Surface notches (1) Tapered notch, (1) Radius notch. • All EDM notches are .004 ± .001 wide. • Finished standard is anodized per MIL-A-8625. • Manufactured IAW U.S.A.F. Tech Order 33B-1-1, Figure 4-39. • NSN 6635-01-092-5129 and P/N 7947479-10