ASME Type Phased Array Pipe Calibration Block (Inch Version) ASME SA516 Gr 70

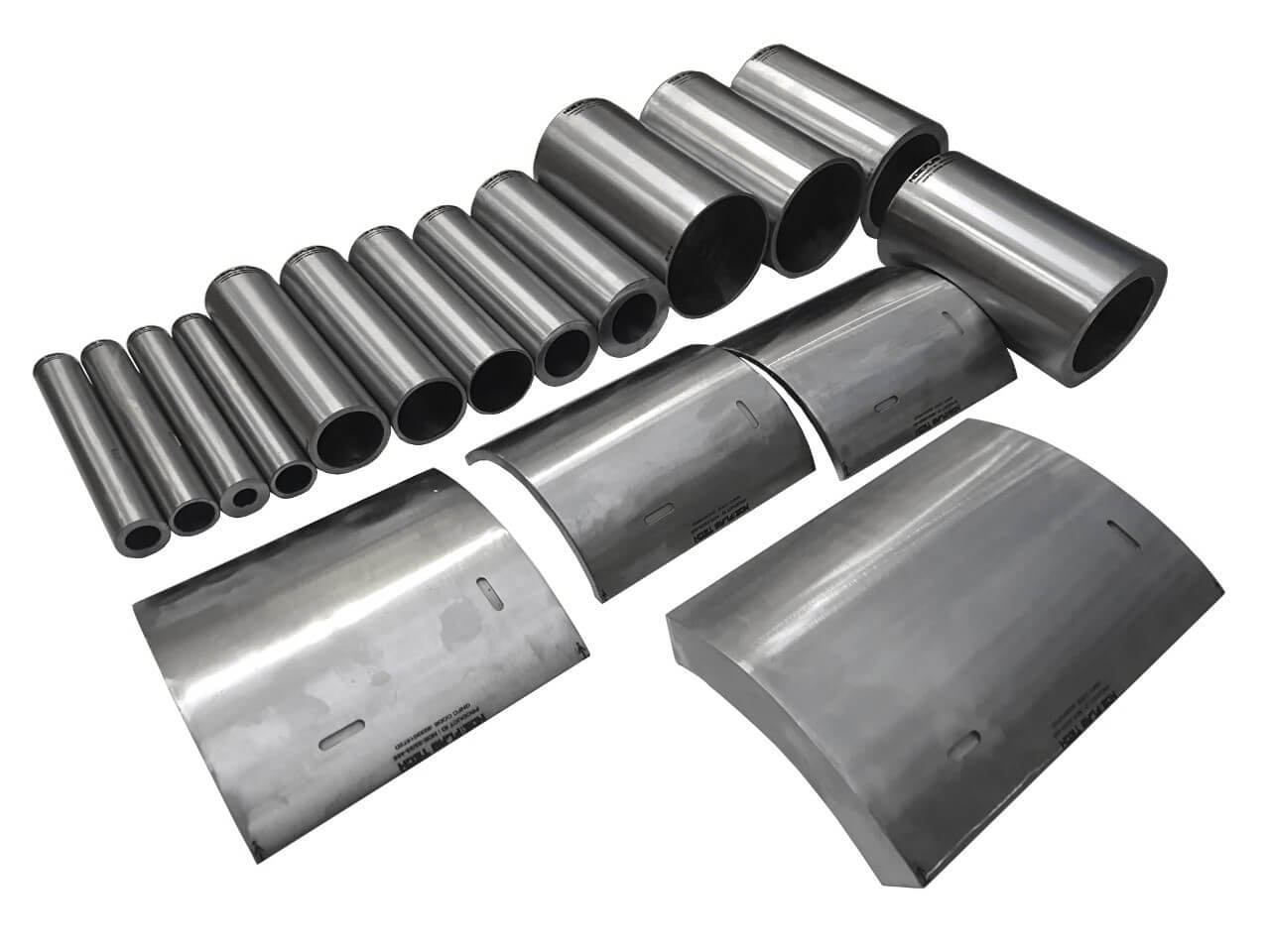

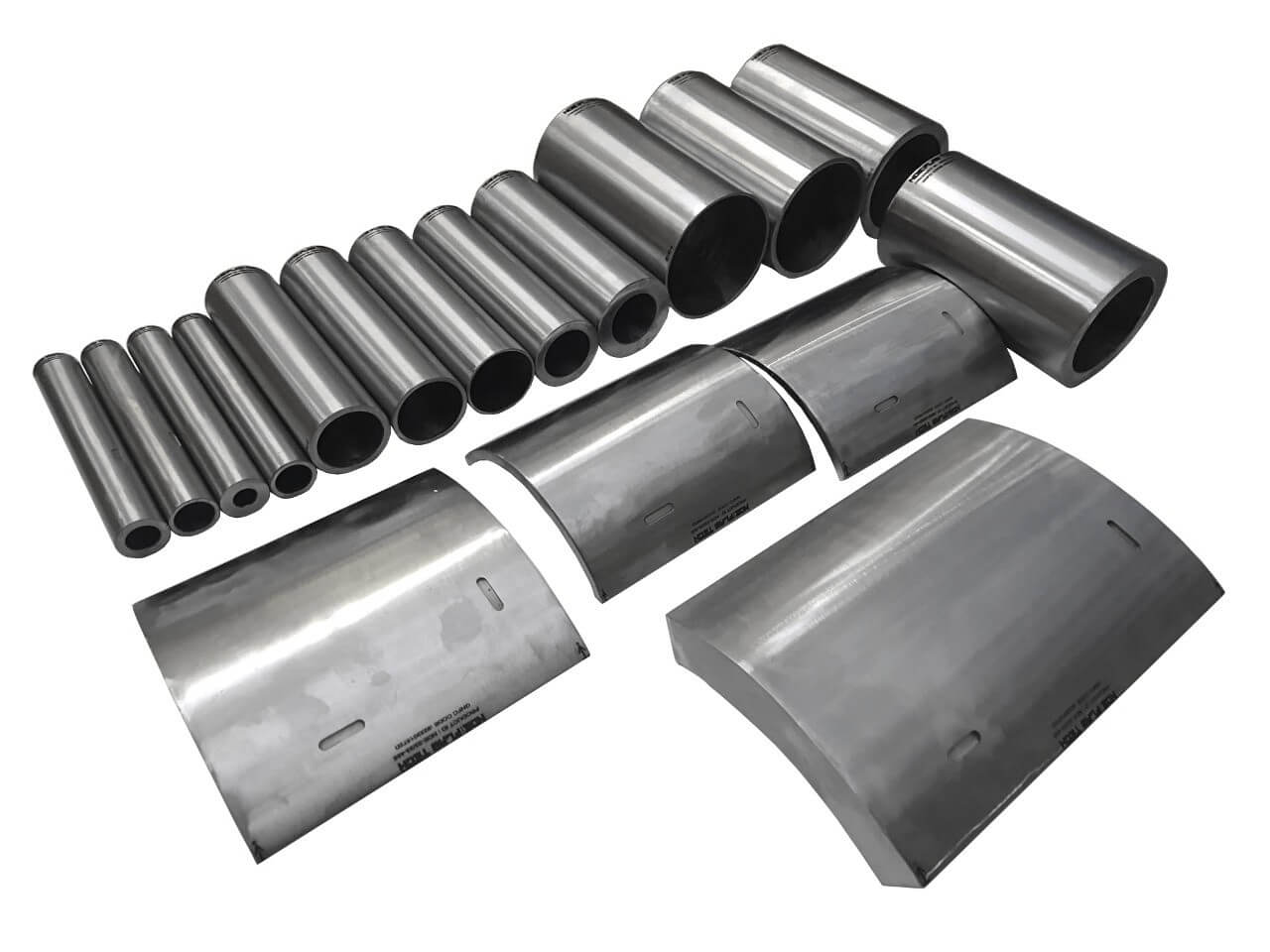

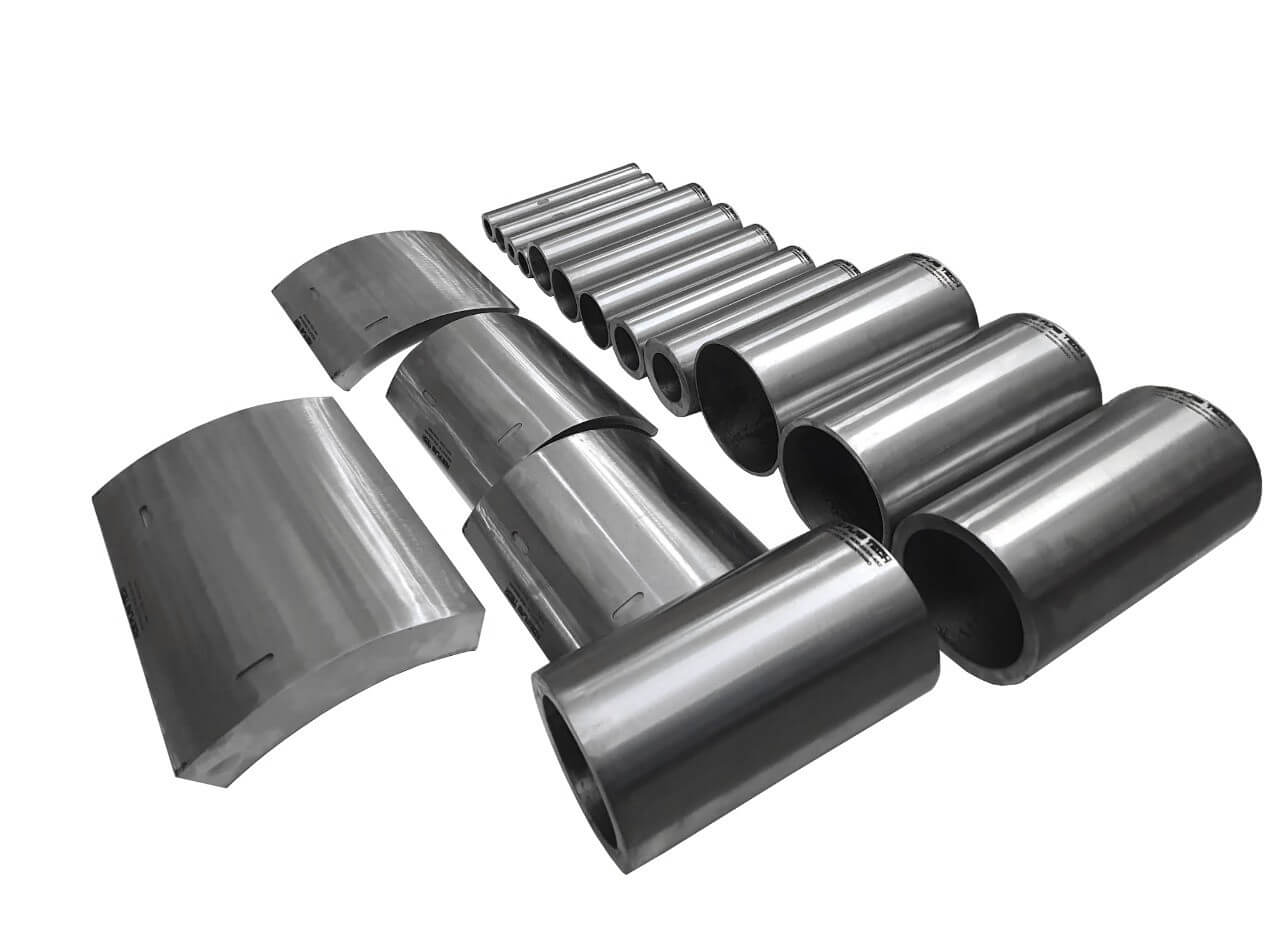

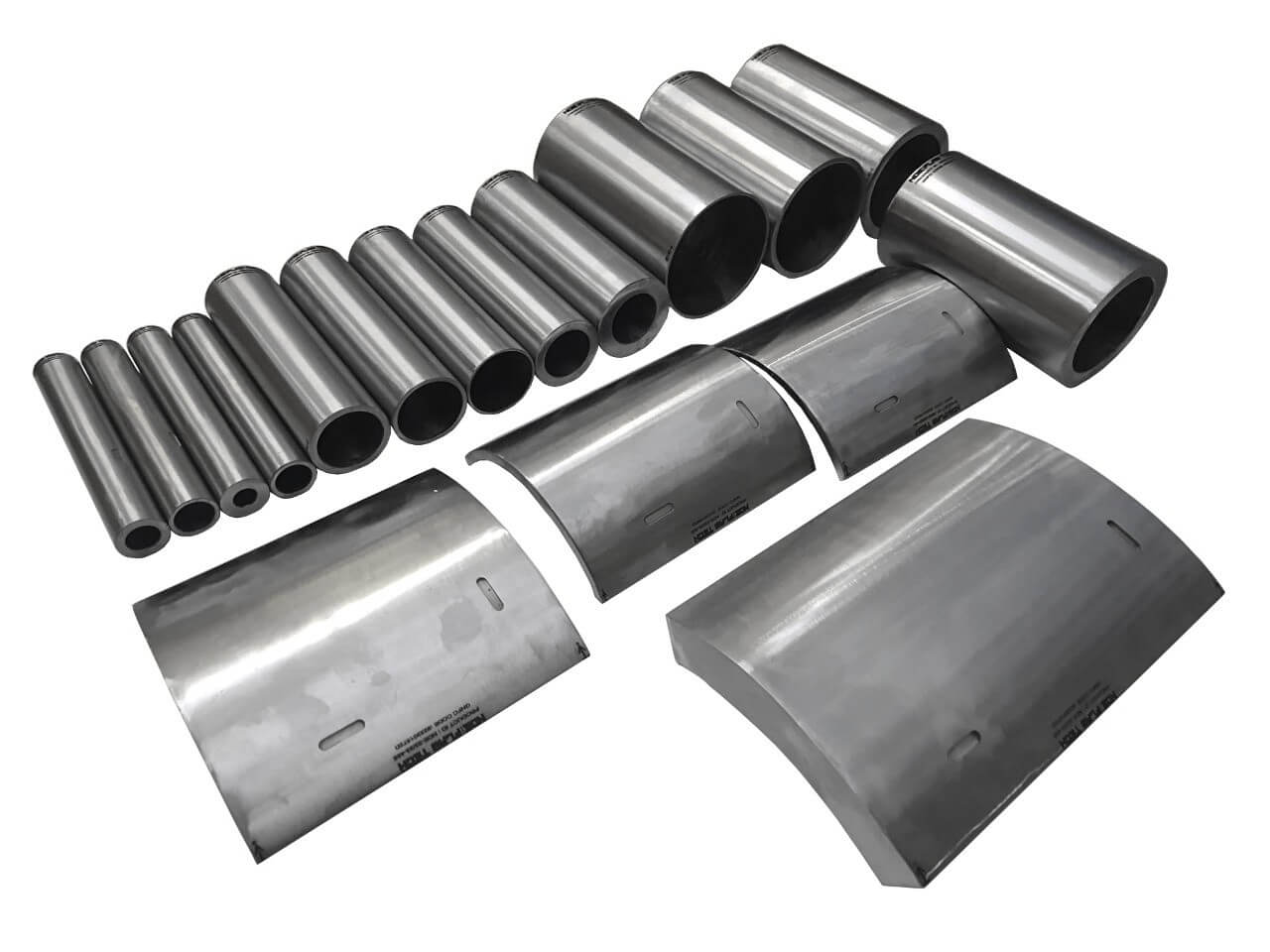

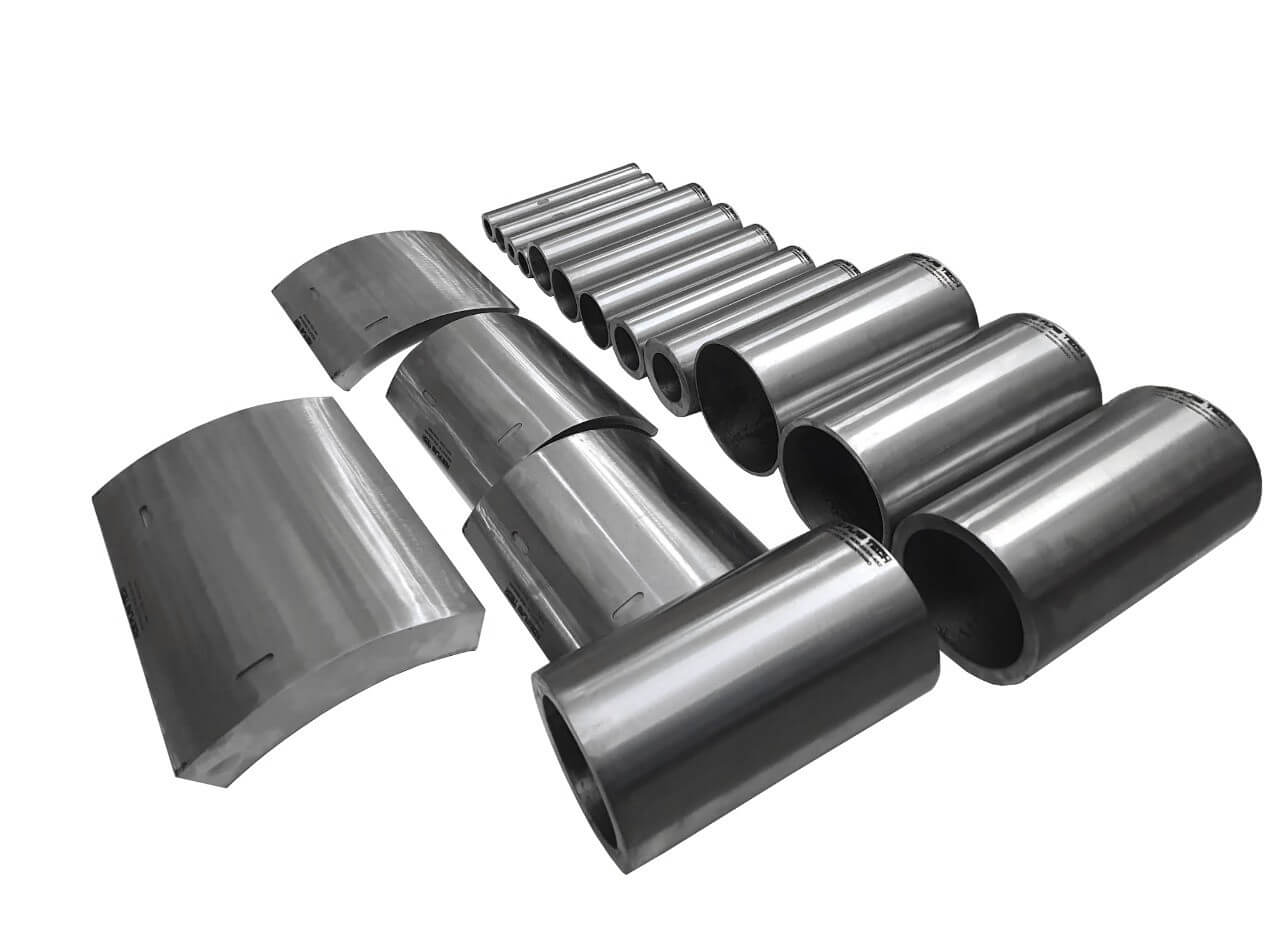

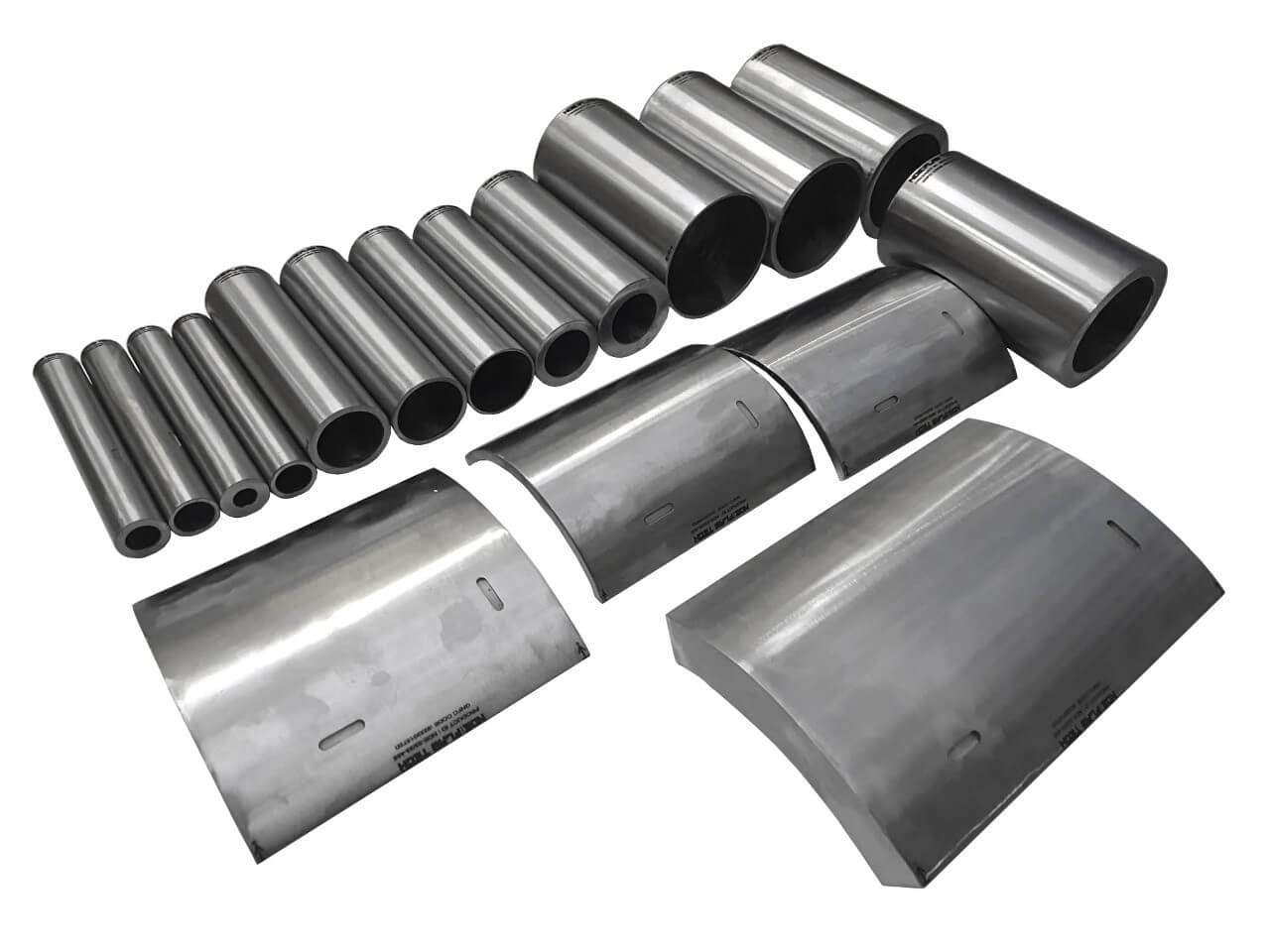

ASME Type Phased Array Pipe Calibration Block (Inch Version) ASME SA516 Gr 70 Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well. The Phased Array Pipe Calibration Block contains 4 EDM notches (axial and circumferential on both OD and ID) at a depth of 8-11% of nominal wall thickness x 1/4" maximum width (most notches are approximately .030" - .040" wide) x 1.000" minimum length. Blocks 5" NPS and smaller are left at 360°, while blocks over 5" are milled to a 180°/120°/90°/60° arc section (depending on nominal pipe size). All blocks are 12" in axial length minimum or 10T, whichever is greater. Made in accordance with ASME Section V Article 4 Figure T-43.3, with PAUT modification for PAUT. MATERIAL: ASME SA516 Gr 70, NOTE: For special alloy request by mail.

ASME Type Phased Array Pipe Calibration Block (Inch Version) ASME SA517

ASME Type Phased Array Pipe Calibration Block (Inch Version) ASME SA517 Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well. The Phased Array Pipe Calibration Block contains 4 EDM notches (axial and circumferential on both OD and ID) at a depth of 8-11% of nominal wall thickness x 1/4" maximum width (most notches are approximately .030" - .040" wide) x 1.000" minimum length. Blocks 5" NPS and smaller are left at 360°, while blocks over 5" are milled to a 180°/120°/90°/60° arc section (depending on nominal pipe size). All blocks are 12" in axial length minimum or 10T, whichever is greater. Made in accordance with ASME Section V Article 4 Figure T-43.3, with PAUT modification for PAUT. MATERIAL: ASME SA517, NOTE: For special alloy request by mail.

ASME Type Phased Array Pipe Calibration Block (Inch Version) ASME SA36 / A 36

ASME Type Phased Array Pipe Calibration Block (Inch Version) ASME SA36 / A 36 Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well. The Phased Array Pipe Calibration Block contains 4 EDM notches (axial and circumferential on both OD and ID) at a depth of 8-11% of nominal wall thickness x 1/4" maximum width (most notches are approximately .030" - .040" wide) x 1.000" minimum length. Blocks 5" NPS and smaller are left at 360°, while blocks over 5" are milled to a 180°/120°/90°/60° arc section (depending on nominal pipe size). All blocks are 12" in axial length minimum or 10T, whichever is greater. Made in accordance with ASME Section V Article 4 Figure T-43.3, with PAUT modification for PAUT. MATERIAL: ASME SA36 / A 36, NOTE: For special alloy request by mail.

ASME Type Phased Array Pipe Calibration Block (Inch Version) STAINLESS STEEL 304

ASME Type Phased Array Pipe Calibration Block (Inch Version) STAINLESS STEEL 304 Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well. The Phased Array Pipe Calibration Block contains 4 EDM notches (axial and circumferential on both OD and ID) at a depth of 8-11% of nominal wall thickness x 1/4" maximum width (most notches are approximately .030" - .040" wide) x 1.000" minimum length. Blocks 5" NPS and smaller are left at 360°, while blocks over 5" are milled to a 180°/120°/90°/60° arc section (depending on nominal pipe size). All blocks are 12" in axial length minimum or 10T, whichever is greater. Made in accordance with ASME Section V Article 4 Figure T-43.3, with PAUT modification for PAUT. MATERIAL: STAINLESS STEEL 304, NOTE: For special alloy request by mail.

ASME Type Phased Array Pipe Calibration Block (Inch Version) STAINLESS STEEL 316

ASME Type Phased Array Pipe Calibration Block (Inch Version) STAINLESS STEEL 316 Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well. The Phased Array Pipe Calibration Block contains 4 EDM notches (axial and circumferential on both OD and ID) at a depth of 8-11% of nominal wall thickness x 1/4" maximum width (most notches are approximately .030" - .040" wide) x 1.000" minimum length. Blocks 5" NPS and smaller are left at 360°, while blocks over 5" are milled to a 180°/120°/90°/60° arc section (depending on nominal pipe size). All blocks are 12" in axial length minimum or 10T, whichever is greater. Made in accordance with ASME Section V Article 4 Figure T-43.3, with PAUT modification for PAUT. MATERIAL: STAINLESS STEEL 316, NOTE: For special alloy request by mail.

ASME Type Phased Array Pipe Calibration Block (Inch Version) TITANIUM

ASME Type Phased Array Pipe Calibration Block (Inch Version) TITANIUM Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well. The Phased Array Pipe Calibration Block contains 4 EDM notches (axial and circumferential on both OD and ID) at a depth of 8-11% of nominal wall thickness x 1/4" maximum width (most notches are approximately .030" - .040" wide) x 1.000" minimum length. Blocks 5" NPS and smaller are left at 360°, while blocks over 5" are milled to a 180°/120°/90°/60° arc section (depending on nominal pipe size). All blocks are 12" in axial length minimum or 10T, whichever is greater. Made in accordance with ASME Section V Article 4 Figure T-43.3, with PAUT modification for PAUT. MATERIAL: TITANIUM, NOTE: For special alloy request by mail.

ASME Type Phased Array Pipe Calibration Block (Inch Version) ALUMINUM

ASME Type Phased Array Pipe Calibration Block (Inch Version) ALUMINUM Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well. The Phased Array Pipe Calibration Block contains 4 EDM notches (axial and circumferential on both OD and ID) at a depth of 8-11% of nominal wall thickness x 1/4" maximum width (most notches are approximately .030" - .040" wide) x 1.000" minimum length. Blocks 5" NPS and smaller are left at 360°, while blocks over 5" are milled to a 180°/120°/90°/60° arc section (depending on nominal pipe size). All blocks are 12" in axial length minimum or 10T, whichever is greater. Made in accordance with ASME Section V Article 4 Figure T-43.3, with PAUT modification for PAUT. MATERIAL: ALUMINUM, NOTE: For special alloy request by mail.

ASME Type Phased Array Pipe Calibration Block (Inch Version) COPPER

ASME Type Phased Array Pipe Calibration Block (Inch Version) COPPER Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well. The Phased Array Pipe Calibration Block contains 4 EDM notches (axial and circumferential on both OD and ID) at a depth of 8-11% of nominal wall thickness x 1/4" maximum width (most notches are approximately .030" - .040" wide) x 1.000" minimum length. Blocks 5" NPS and smaller are left at 360°, while blocks over 5" are milled to a 180°/120°/90°/60° arc section (depending on nominal pipe size). All blocks are 12" in axial length minimum or 10T, whichever is greater. Made in accordance with ASME Section V Article 4 Figure T-43.3, with PAUT modification for PAUT. MATERIAL: COPPER, NOTE: For special alloy request by mail.

ASME Type Phased Array Pipe Calibration Block (Inch Version) INCONEL 625

ASME Type Phased Array Pipe Calibration Block (Inch Version) INCONEL 625 Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well. The Phased Array Pipe Calibration Block contains 4 EDM notches (axial and circumferential on both OD and ID) at a depth of 8-11% of nominal wall thickness x 1/4" maximum width (most notches are approximately .030" - .040" wide) x 1.000" minimum length. Blocks 5" NPS and smaller are left at 360°, while blocks over 5" are milled to a 180°/120°/90°/60° arc section (depending on nominal pipe size). All blocks are 12" in axial length minimum or 10T, whichever is greater. Made in accordance with ASME Section V Article 4 Figure T-43.3, with PAUT modification for PAUT. MATERIAL: INCONEL 625, NOTE: For special alloy request by mail.

ASME Type Phased Array Pipe Calibration Block (Inch Version) INCONEL 825

ASME Type Phased Array Pipe Calibration Block (Inch Version) INCONEL 825 Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well. The Phased Array Pipe Calibration Block contains 4 EDM notches (axial and circumferential on both OD and ID) at a depth of 8-11% of nominal wall thickness x 1/4" maximum width (most notches are approximately .030" - .040" wide) x 1.000" minimum length. Blocks 5" NPS and smaller are left at 360°, while blocks over 5" are milled to a 180°/120°/90°/60° arc section (depending on nominal pipe size). All blocks are 12" in axial length minimum or 10T, whichever is greater. Made in accordance with ASME Section V Article 4 Figure T-43.3, with PAUT modification for PAUT. MATERIAL: INCONEL 825, NOTE: For special alloy request by mail.

ASME Type Phased Array Pipe Calibration Block (Inch Version) MONAL 800

ASME Type Phased Array Pipe Calibration Block (Inch Version) MONAL 800 Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well. The Phased Array Pipe Calibration Block contains 4 EDM notches (axial and circumferential on both OD and ID) at a depth of 8-11% of nominal wall thickness x 1/4" maximum width (most notches are approximately .030" - .040" wide) x 1.000" minimum length. Blocks 5" NPS and smaller are left at 360°, while blocks over 5" are milled to a 180°/120°/90°/60° arc section (depending on nominal pipe size). All blocks are 12" in axial length minimum or 10T, whichever is greater. Made in accordance with ASME Section V Article 4 Figure T-43.3, with PAUT modification for PAUT. MATERIAL: MONAL 800, NOTE: For special alloy request by mail.

ASME Type Phased Array Pipe Calibration Block (Inch Version) NICKEL

ASME Type Phased Array Pipe Calibration Block (Inch Version) NICKEL Ready to request a quote for some blocks? Here's what we need... What is the pipe material? What is the pipe NPS / OD size? What is the pipe schedule / wall thickness? Is NDE FLAW supplying the material or will it be customer supplied? Are there any changes or modifications requested to our block design? Drop us an e-mail with the above information. These pipe calibration blocks are specially designed to facilitate phased array UT (PAUT). The NDE FLAW block design includes various modifications to the original ASME design, including extra axial and arc length, a rearranged notch layout and a 10° angled cut on one end for blocks over 5" NPS. These modifications help to minimize unwanted "noise" from the back wall while performing DAC/TCG calibrations with phased array UT equipment. A calibration block should be a section of pipe of the same nominal size, schedule, and heat treatment and material specifications as the material being examined. We maintain a large inventory of raw material for the machining of these standards and they can be made from customer supplied material as well. The Phased Array Pipe Calibration Block contains 4 EDM notches (axial and circumferential on both OD and ID) at a depth of 8-11% of nominal wall thickness x 1/4" maximum width (most notches are approximately .030" - .040" wide) x 1.000" minimum length. Blocks 5" NPS and smaller are left at 360°, while blocks over 5" are milled to a 180°/120°/90°/60° arc section (depending on nominal pipe size). All blocks are 12" in axial length minimum or 10T, whichever is greater. Made in accordance with ASME Section V Article 4 Figure T-43.3, with PAUT modification for PAUT. MATERIAL: NICKEL, NOTE: For special alloy request by mail.