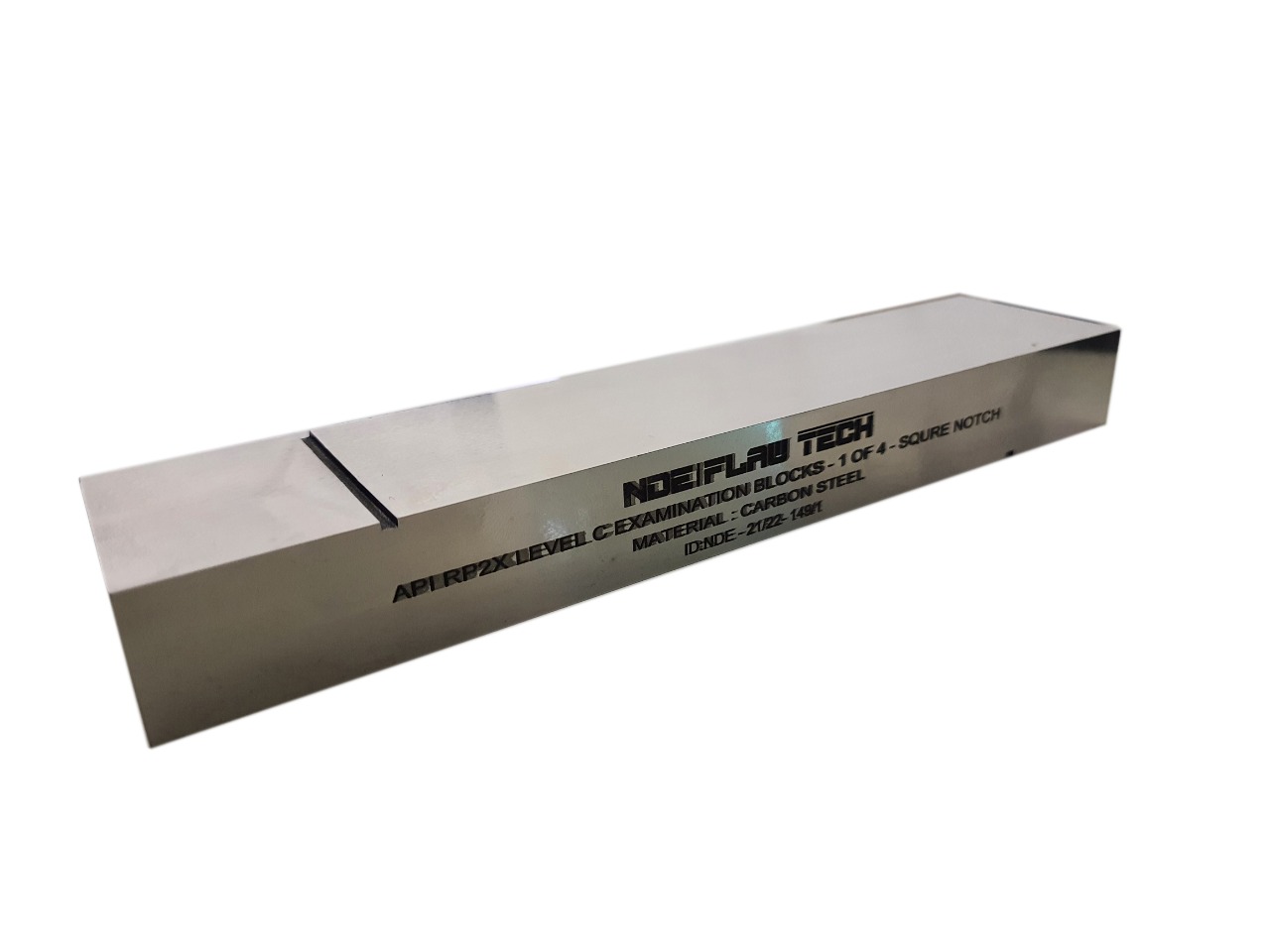

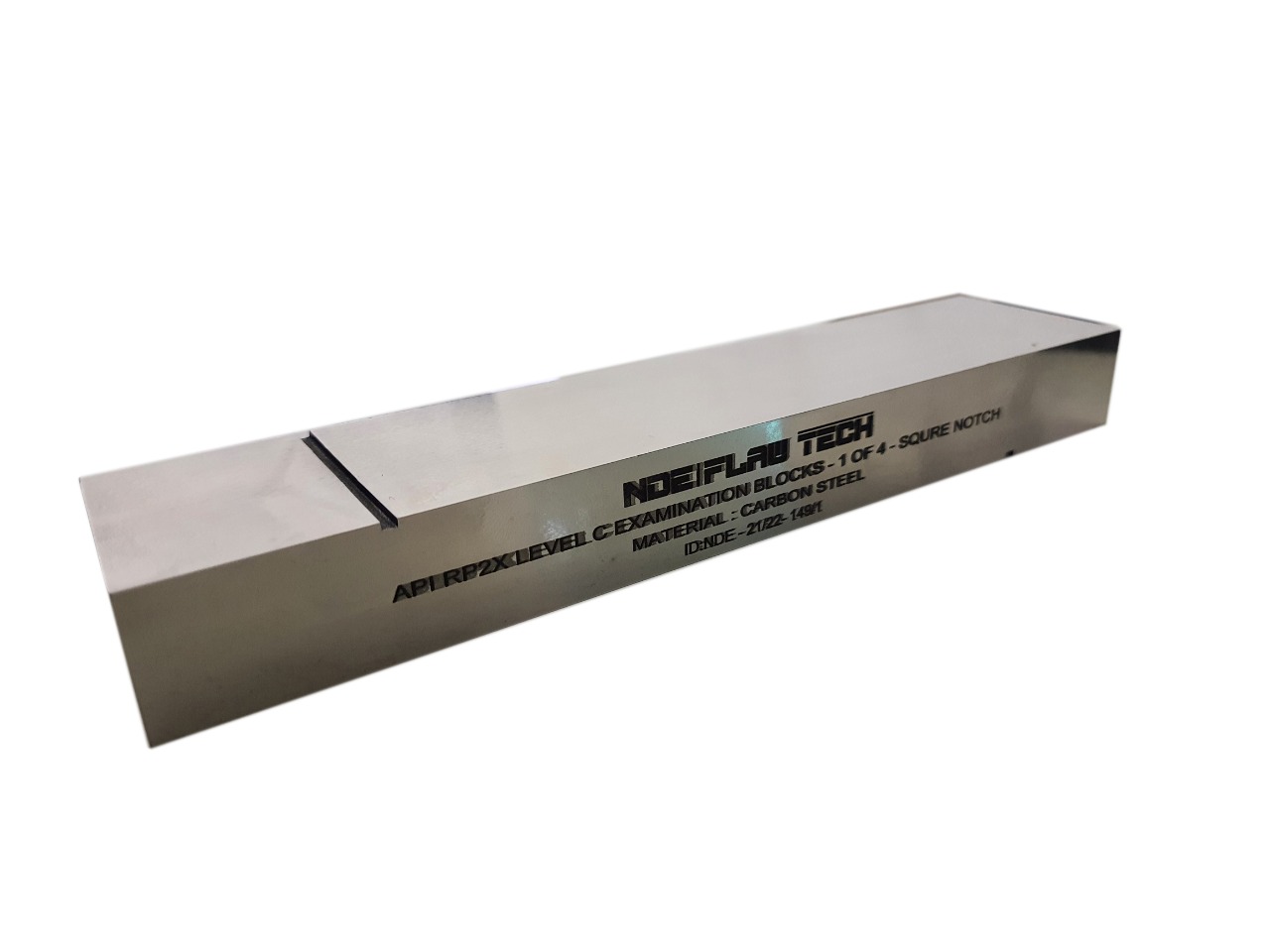

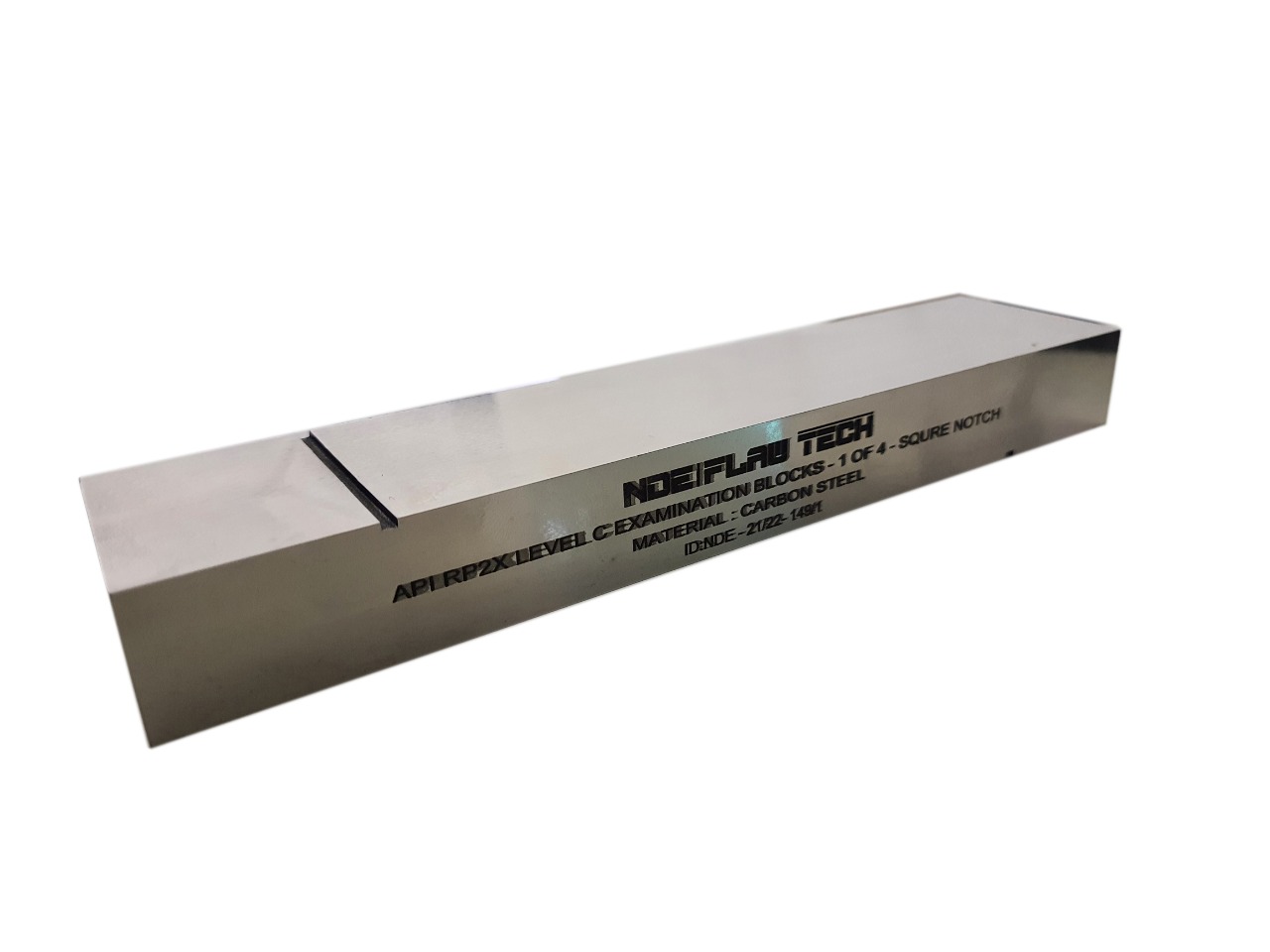

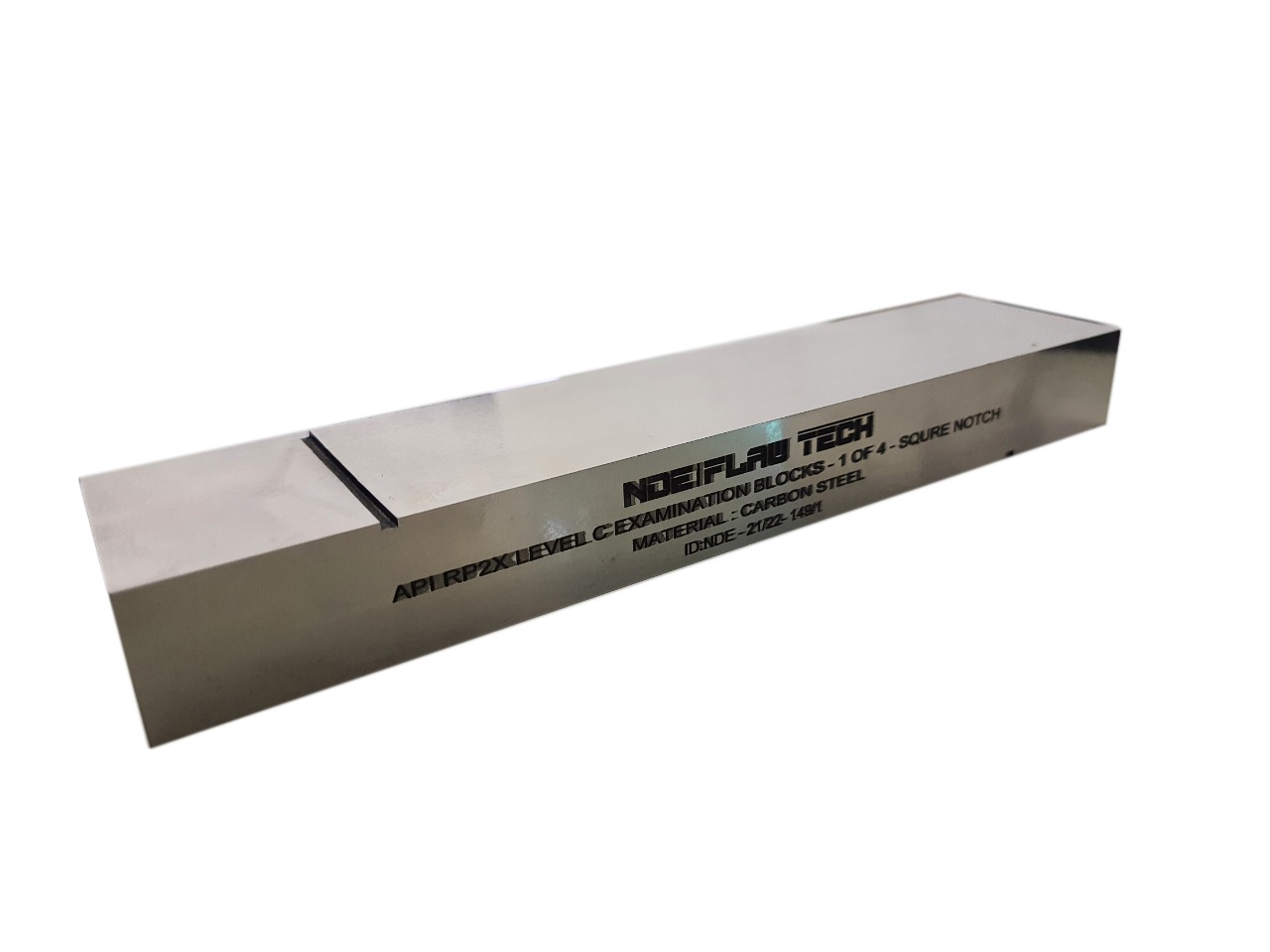

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) Special Alloy

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) Special Alloy The reference reflector for establishing the scanning sensitivity must be compatible with the flaw acceptance criteria and provide sufficient sensitivity to ensure detection of the smallest discontinuity of interest. For ultrasonic examination at Level A acceptance criteria, the side of a 1/16-inch (1.6-millimeter) drilled hole provides an excellent reference for use with all transducers. The thickness and length of the block containing the drilled hole should permit evaluation of reference sensitivity at the longest metal path distance anticipated in the actual examination. In addition to the side-drilled holes employed for evaluation of all discontinuities in the body of the weld, two 1/16-inch deep notches are suggested as reference standards to be used in evaluating root reflector in butt or T, K, and Y connections welded from one side only. DIMENSION : 228mm (L) X 50mm (W) X 25mm (T) Note : “T” based on the material and equipment that will be used. Block Contains : One Side Drill Hole of Dia Ø1.6mm Deep 38mm Two notch 50mm(L) X 2.38mm (W) X 1.6mm (D) Material : Special Alloy

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) 4340 Steel

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) 4340 Steel The reference reflector for establishing the scanning sensitivity must be compatible with the flaw acceptance criteria and provide sufficient sensitivity to ensure detection of the smallest discontinuity of interest. For ultrasonic examination at Level A acceptance criteria, the side of a 1/16-inch (1.6-millimeter) drilled hole provides an excellent reference for use with all transducers. The thickness and length of the block containing the drilled hole should permit evaluation of reference sensitivity at the longest metal path distance anticipated in the actual examination. In addition to the side-drilled holes employed for evaluation of all discontinuities in the body of the weld, two 1/16-inch deep notches are suggested as reference standards to be used in evaluating root reflector in butt or T, K, and Y connections welded from one side only. DIMENSION : 228mm (L) X 50mm (W) X 25mm (T) Note : “T” based on the material and equipment that will be used. Block Contains : One Side Drill Hole of Dia Ø1.6mm Deep 38mm Two notch 50mm(L) X 2.38mm (W) X 1.6mm (D) Material : 4340 Steel

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) 1018 Steel

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) 1018 Steel The reference reflector for establishing the scanning sensitivity must be compatible with the flaw acceptance criteria and provide sufficient sensitivity to ensure detection of the smallest discontinuity of interest. For ultrasonic examination at Level A acceptance criteria, the side of a 1/16-inch (1.6-millimeter) drilled hole provides an excellent reference for use with all transducers. The thickness and length of the block containing the drilled hole should permit evaluation of reference sensitivity at the longest metal path distance anticipated in the actual examination. In addition to the side-drilled holes employed for evaluation of all discontinuities in the body of the weld, two 1/16-inch deep notches are suggested as reference standards to be used in evaluating root reflector in butt or T, K, and Y connections welded from one side only. DIMENSION : 228mm (L) X 50mm (W) X 25mm (T) Note : “T” based on the material and equipment that will be used. Block Contains : One Side Drill Hole of Dia Ø1.6mm Deep 38mm Two notch 50mm(L) X 2.38mm (W) X 1.6mm (D) Material : 1018 Steel

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) STAINLESS STEEL 304

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) STAINLESS STEEL 304 The reference reflector for establishing the scanning sensitivity must be compatible with the flaw acceptance criteria and provide sufficient sensitivity to ensure detection of the smallest discontinuity of interest. For ultrasonic examination at Level A acceptance criteria, the side of a 1/16-inch (1.6-millimeter) drilled hole provides an excellent reference for use with all transducers. The thickness and length of the block containing the drilled hole should permit evaluation of reference sensitivity at the longest metal path distance anticipated in the actual examination. In addition to the side-drilled holes employed for evaluation of all discontinuities in the body of the weld, two 1/16-inch deep notches are suggested as reference standards to be used in evaluating root reflector in butt or T, K, and Y connections welded from one side only. DIMENSION : 228mm (L) X 50mm (W) X 25mm (T) Note : “T” based on the material and equipment that will be used. Block Contains : One Side Drill Hole of Dia Ø1.6mm Deep 38mm Two notch 50mm(L) X 2.38mm (W) X 1.6mm (D) Material : STAINLESS STEEL 304.

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) STAINLESS STEEL 316

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) STAINLESS STEEL 316 The reference reflector for establishing the scanning sensitivity must be compatible with the flaw acceptance criteria and provide sufficient sensitivity to ensure detection of the smallest discontinuity of interest. For ultrasonic examination at Level A acceptance criteria, the side of a 1/16-inch (1.6-millimeter) drilled hole provides an excellent reference for use with all transducers. The thickness and length of the block containing the drilled hole should permit evaluation of reference sensitivity at the longest metal path distance anticipated in the actual examination. In addition to the side-drilled holes employed for evaluation of all discontinuities in the body of the weld, two 1/16-inch deep notches are suggested as reference standards to be used in evaluating root reflector in butt or T, K, and Y connections welded from one side only. DIMENSION : 228mm (L) X 50mm (W) X 25mm (T) Note : “T” based on the material and equipment that will be used. Block Contains : One Side Drill Hole of Dia Ø1.6mm Deep 38mm Two notch 50mm(L) X 2.38mm (W) X 1.6mm (D) Material : STAINLESS STEEL 316.

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) TITANIUM

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) TITANIUM The reference reflector for establishing the scanning sensitivity must be compatible with the flaw acceptance criteria and provide sufficient sensitivity to ensure detection of the smallest discontinuity of interest. For ultrasonic examination at Level A acceptance criteria, the side of a 1/16-inch (1.6-millimeter) drilled hole provides an excellent reference for use with all transducers. The thickness and length of the block containing the drilled hole should permit evaluation of reference sensitivity at the longest metal path distance anticipated in the actual examination. In addition to the side-drilled holes employed for evaluation of all discontinuities in the body of the weld, two 1/16-inch deep notches are suggested as reference standards to be used in evaluating root reflector in butt or T, K, and Y connections welded from one side only. DIMENSION : 228mm (L) X 50mm (W) X 25mm (T) Note : “T” based on the material and equipment that will be used. Block Contains : One Side Drill Hole of Dia Ø1.6mm Deep 38mm Two notch 50mm(L) X 2.38mm (W) X 1.6mm (D) Material : TITANIUM.

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) ALUMINUM 7075-T6

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) ALUMINUM 7075-T6 The reference reflector for establishing the scanning sensitivity must be compatible with the flaw acceptance criteria and provide sufficient sensitivity to ensure detection of the smallest discontinuity of interest. For ultrasonic examination at Level A acceptance criteria, the side of a 1/16-inch (1.6-millimeter) drilled hole provides an excellent reference for use with all transducers. The thickness and length of the block containing the drilled hole should permit evaluation of reference sensitivity at the longest metal path distance anticipated in the actual examination. In addition to the side-drilled holes employed for evaluation of all discontinuities in the body of the weld, two 1/16-inch deep notches are suggested as reference standards to be used in evaluating root reflector in butt or T, K, and Y connections welded from one side only. DIMENSION : 228mm (L) X 50mm (W) X 25mm (T) Note : “T” based on the material and equipment that will be used. Block Contains : One Side Drill Hole of Dia Ø1.6mm Deep 38mm Two notch 50mm(L) X 2.38mm (W) X 1.6mm (D) Material : ALUMINUM 7075-T6

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) INCONEL 625

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) INCONEL 625 The reference reflector for establishing the scanning sensitivity must be compatible with the flaw acceptance criteria and provide sufficient sensitivity to ensure detection of the smallest discontinuity of interest. For ultrasonic examination at Level A acceptance criteria, the side of a 1/16-inch (1.6-millimeter) drilled hole provides an excellent reference for use with all transducers. The thickness and length of the block containing the drilled hole should permit evaluation of reference sensitivity at the longest metal path distance anticipated in the actual examination. In addition to the side-drilled holes employed for evaluation of all discontinuities in the body of the weld, two 1/16-inch deep notches are suggested as reference standards to be used in evaluating root reflector in butt or T, K, and Y connections welded from one side only. DIMENSION : 228mm (L) X 50mm (W) X 25mm (T) Note : “T” based on the material and equipment that will be used. Block Contains : One Side Drill Hole of Dia Ø1.6mm Deep 38mm Two notch 50mm(L) X 2.38mm (W) X 1.6mm (D) Material : INCONEL 625.

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) MONAL 800

API RP 2X Reference Standards LEVEL A BLOCK (METRIC VERSION) MONAL 800 The reference reflector for establishing the scanning sensitivity must be compatible with the flaw acceptance criteria and provide sufficient sensitivity to ensure detection of the smallest discontinuity of interest. For ultrasonic examination at Level A acceptance criteria, the side of a 1/16-inch (1.6-millimeter) drilled hole provides an excellent reference for use with all transducers. The thickness and length of the block containing the drilled hole should permit evaluation of reference sensitivity at the longest metal path distance anticipated in the actual examination. In addition to the side-drilled holes employed for evaluation of all discontinuities in the body of the weld, two 1/16-inch deep notches are suggested as reference standards to be used in evaluating root reflector in butt or T, K, and Y connections welded from one side only. DIMENSION : 228mm (L) X 50mm (W) X 25mm (T) Note : “T” based on the material and equipment that will be used. Block Contains : One Side Drill Hole of Dia Ø1.6mm Deep 38mm Two notch 50mm(L) X 2.38mm (W) X 1.6mm (D) Material : MONAL 800.